|

|

|

Figure 1: The effect of sugarcane molasses and ground maize levels on the pH value of water hyacinth silage during fermentation period |

|

Live stock production, climate change and resource depletion |

The objective of this study was to determine the effects of molasses and ground maize as additives to make water hyacinth silage. The experiment was a completely randomized design with 7 treatments and 3 replications. The treatments included 0, 7.70, 11.5, and 15.3% for both sugarcane molasses and ground maize. The observation was done at day 0, 7,14, 28 and 56. The wilting WH was chopped to 2-3 cm and completely mixed with additives. Plastic bags were used for incubation as experimental units.

The results showed that pH values were significantly different among treatments (P< 0.05) at different incubated days. The pH at day 14 was 5.50, 4.45, 4.25, 4.22, 4.83, 4.76 and 4.59 for the treatments of 0, 7.70, 11.5, and 15.3% of molasses and 7.70, 11.5, and 15.3% of ground maize, respectively. The chemical composition of water hyacinth silage was not significantly different (P>0.05) among the treatments at different observed days, except CP content. From day 14 to 56, CP contents of WH silage made by molasses were significantly higher (P<0.05) than those of ground maize at the same levels of treating. Ensiling water hyacinth with molasses at the levels of 11.5 and 15.3% had the sour vinegar smell and light yellow color. The results of this study implied that treating water hyacinth with 11.5% molasses (DM basis) could be used for making a good silage .

In Mekong delta, the thick density of lakes, ponds, canals and rivers supports to the development of aquatic plant, especially water hyacinth. Water hyacinth grows rapidly causing direct obstruction to navigation, fishing, life environment and other commercial activities whose survival depend upon the waterways (Kusemiju and Chizea, 1992). However, it is considered as cheap source of biogas, animal feed and bio fertilizers (Bagnal et al,1974 and Shiralipour and Smith, 1984). Besides water hyacinth also is material to produce exported hand-make products or mushroom cultivation. Taylor (1969) stated that water hyacinth as a high quality protein source. Water hyacinth can be successfully incorporated in ruminants diets El-Serafy et al (1981). Fresh water hyacinth fed to cattle is limited because of its extremely high moisture content, rapid deterioration and spoilage (Hentges et al., 1972).

Silage is a method of high moisture forage preservation by acids produced during the fermentation. Bacteria ferment carbohydrate in the plant to organic acids that lower the pH of the silage to levels that inhibit further microbial fermentation (Ranjit and Kung, 2000). The goal is a rapid pH drop to minimize fermentation losses of feedstuff nutrients, especially protein.The water hyacinth has low concentrations of fermentable carbohydrates and the addition of additives can improve the quality of its. Using molasses or corn as additive can increase the amount of fermentation end products due to fermentation of the available carbohydrate (Yakota et al., 1992). The aim of this study was to determine effects of sugarcane molasses and ground maize as additives on chemical composition, color and smell of water hyacinth silage for making a better silage.

The experiments were carried out in the experimental farm of Department of Animal Husbandry, College of Agriculture and Applied biology, Cantho University from January to May in 2009.

The experimental design was a completely randomized with 7 treatments and 3 replications. The treatments were WH with no additives (NA), WH treated with 7.7% molasses (7.7M), 11.5% molasses (11.5M), 15.3% molasses (15.3M), 7.7% ground maize (7.7GM), 11.5% ground maize (11.5GM) and 15.3% ground maize (15.3GM) based on DM basis.

Water hyacinth was collected from rivers near Cantho University and washed with clean water after removing the root. It was wilted (approximate DM content of 17%) by sun drying and chopped to 2-3 cm and completely mixed with additives and placed in the plastic bags. Plastic bags of 3 kg were used for incubation as experimental units. Materials were compacted by hand pressing in two-layer bags.

The observation was done at day 0, 7,14, 28 and 56 after ensiling

The silage were taken for evaluating of pH, color and smell, and analysing of DM, OM, CP, ash (AOAC, 1990). NDF was analyzed following procedure described by Van Soest et al. (1991).

The data were analyzed by analysis of variance using the ANOVA of General Linear Model of Minitab Reference Manual Release 13.21 (Minitab, 2000).

|

Table 1: Effect of sugarcane molasses and ground maize levels as additives on pH of water hyacinth silage |

|||||||||

|

Incubated time (day) |

Treatment |

P |

ąSE |

||||||

|

NA |

M7.7 |

M11.5 |

M15.3 |

GM7.7 |

GM11.5 |

GM15.3 |

|||

|

0 |

6.31d |

5.04bc |

4.89c |

4.75c |

5.49a |

5.41a |

5.35ab |

0.001 |

0.094 |

|

7 |

5.91c |

4.67b |

4.51bd |

4.35d |

5.09a |

5.09a |

4.74b |

0.001 |

0.086 |

|

14 |

5.50c |

4.45db |

4.25d |

4.22d |

4.83a |

4.76a |

4.59ab |

0.001 |

0.082 |

|

28 |

5.12d |

4.43ab |

4.14be |

4.06e |

4.68c |

4.57abc |

4.34b |

0.001 |

0.066 |

|

56 |

5.05d |

4.34ab |

4.06ce |

4.00e |

4.54a |

4.45ab |

4.27bc |

0.001 |

0.072 |

|

a, b, c, d, e

Means with different letters within the same rows are significantly

different at the 5% level. |

|||||||||

Table 1 showed that the effect of adding additives and time of ensiling on the pH of water hyacinth silage. In general the treatments, which were treated with sugarcane molasses, dropped rapidly pH value at day 7 and had the lower values compared to the others. The pH values of the treatment M11.5 and M15.3 were 4.89 and 4.75, respectively at the first day of ensiling. At 14th day after ensiling, there was significantly different on pH values among the treatments (P<0.01). The result of the treatment M15.3 being 4.22 in this study was similar to the pH values stated by Mahala and Khalifa (2007) being 4.2 after ensiling sorghum with 15% molasses for 25 days. The water hyacinth silage without additive was higher pH value than that of the others. Treating water hyacinth with ground maize also reduced pH values. The treatments added molasses fermented more rapidly as compared to others. At 28th day after ensiling, the pH values were 4.14 and 4.06 for the treatment M11.5 and M15.3, respectively and were stable up to 56th day. The pH value of water hyacinth silage without additives in this study was similar to that reported by Lowilai (1994). Kung and Shaver (2002) in their interpretation of silage analysis stated that a good quality grass and legume silage-pH values in the tropics ranged between 4.30 and 4.70.

|

|

|

Figure 1: The effect of sugarcane molasses and ground maize levels on the pH value of water hyacinth silage during fermentation period |

DM, OM, Ash content of water hyacinth silage

The effects of ensiling on the DM, OM and ash content of the EWH were showed in Table 2, 3 and 4.

|

Table 2: Effect of sugarcane molasses and ground maize levels as additives on DM content of water hyacinth silage |

|||||||||

|

Incubated time (day) |

Treatment |

P |

ąSE |

||||||

|

NA |

M7.7 |

M11.5 |

M15.3 |

GM7.7 |

GM11.5 |

GM15.3 |

|||

|

0 |

17.7 |

17.6 |

18.1 |

17.8 |

17.3 |

17.9 |

18.3 |

0.224 |

0.350 |

|

7 |

16.9 |

17.4 |

17.8 |

17.7 |

17.0 |

17.6 |

17.9 |

0.050 |

0.301 |

|

14 |

16.4 |

16.9 |

17.3 |

17.5 |

16.8 |

17.1 |

17.4 |

0.250 |

0.452 |

|

28 |

16.0 |

16.4 |

17.2 |

17.3 |

16.5 |

16.9 |

17.1 |

0.078 |

0.419 |

|

56 |

15.7b |

16.3abc |

17.0ac |

17.2c |

16.0ab |

16.7abc |

17.0a |

0.002 |

0.307 |

|

a, b,c

Means with different letters within the same rows are significantly

different at the 5% level. |

|||||||||

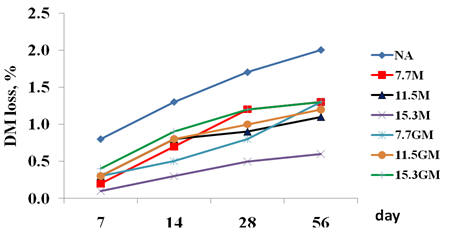

The DM content of water hyacinth silage was not significantly different among treatments (P>0.05) from day 0 to day 28. The silage DM was lower for the treatment without additives. Because of adding sugarcane molasses and ground maize. At 14th day after ensiling, the DM value of the treatment M15.4 (17.5%) was the highest among the treatments. The DM content of all the treatments reduced gradually during storage time. This agreed with the report of Nguyen Van Hiep et al. (2008). There was a significant difference of DM among the treatments. The DM content of the NA treatment was the lowest value (15.7%) and it was significantly lower than M11.5, M15.3 and GM15.3 treatments. However no significant difference (P>0.05) was found among the treatments of M11.5, GM11.5 and M15.3. The DM contents of water hyacinth silage in this study were lower than those stated by Nisa et al. (2006) being 17.5-18.3% after 40 days of ensiling. The Figure 2 also indicated that the lowest DM loss (%) EWH was for 15.3M treatment.

|

| Figure 2: The loss of DM content of water hyacinth treated with Sugarcane molasses and ground maize levels during fermentation period |

|

Table 3: Effect of sugarcane molasses and ground maize levels as additives on OM content (DM basis) of water hyacinth silage |

|||||||||

|

Incubated time (day) |

Treatment |

P |

ąSE |

||||||

|

NA |

M7.7 |

M11.5 |

M15.3 |

GM7.7 |

GM11.5 |

GM15.3 |

|||

|

0 |

82.8 |

83.1 |

82.6 |

83.3 |

82.9 |

83.1 |

83.0 |

0.371 |

0.273 |

|

7 |

82.4 |

82.7 |

82.5 |

83.0 |

82.5 |

82.8 |

82.7 |

0.967 |

0.611 |

|

14 |

81.8 |

82.6 |

82.3 |

82.8 |

82.0 |

82.4 |

82.4 |

0.651 |

0.550 |

|

28 |

81.2 |

82.1 |

82.3 |

82.5 |

81.7 |

82.3 |

82.0 |

0.139 |

0.433 |

|

56 |

79.9 |

81.3 |

82.0 |

82.4 |

80.4 |

81.8 |

82.0 |

0.099 |

0.853 |

|

NA: water hyacinth without

additives |

|||||||||

The OM content of water hyacinth silage decreased gradually in all treatments during incubation time. There was no significant difference (P>0.05) in term of OM content among the treatments, despite DM of water hyacinth silage made by the additives was slightly higher than that of the NA treatment. In general the loss of OM content in the treatment treated with molasses tended to decrease slowly. The OM content was not significantly different (P>0.05) among the treatments.

|

Table 4: Effect of sugarcane molasses and ground maize levels as additives on ash content (DM basis) of water hyacinth silage |

|||||||||

|

Incubated time (day) |

Treatment |

P |

ąSE |

||||||

|

NA |

M7.7 |

M11.5 |

M15.3 |

GM7.7 |

GM11.5 |

GM15.3 |

|||

|

0 |

17.2 |

16.9 |

17.4 |

16.8 |

17.1 |

16.9 |

17.0 |

0.461 |

0.270 |

|

7 |

17.6 |

17.3 |

17.5 |

17.0 |

17.5 |

17.2 |

17.4 |

0.962 |

0.599 |

|

14 |

18.2 |

17.4 |

17.7 |

17.2 |

18.0 |

17.6 |

17.6 |

0.665 |

0.543 |

|

28 |

18.8 |

17.9 |

17.8 |

17.5 |

18.3 |

17.7 |

18.0 |

0.129 |

0.430 |

|

56 |

20.1 |

18.7 |

18.0 |

17.6 |

19.6 |

18.2 |

18.0 |

0.99 |

0.856 |

|

NA: water hyacinth without

additives |

|||||||||

Table 4 showed the ash content of water hyacinth silage at different incubation times. No significant difference was found on this item among the treatments (P>0.05). The tendency of the Ash content was opposite to the OM content. At 28th day after ensiling, the ash content of silage in this study was slightly higher than that found by Lowilai et al. (1994) as water hyacinth treated with different rice bran levels. After 56 days of incubation treating water hyacinth silage without additives was the highest value (20.1%), following in the treatment added ground maize (18.2 19.6 %).

CP and NDF content of water hyacinth silage

Crude protein and NDF content of water hyacinth silages were showed in Table 5 and 6

|

Table 5: Effect of sugarcane molasses and ground maize levels as additives on CP content (DM basis) of water hyacinth silage |

|||||||||

|

Incubated time (day) |

Treatment |

P |

ąSE |

||||||

|

NA |

M7.7 |

M11.5 |

M15.3 |

GM7.7 |

GM11.5 |

GM15.3 |

|||

|

0 |

12.4 |

12.1 |

11.9 |

12.2 |

12.0 |

12.1 |

11.9 |

0.791 |

0.328 |

|

7 |

11.6 |

11.9 |

11.8 |

12.0 |

11.6 |

12.0 |

11.8 |

0.282 |

0.199 |

|

14 |

10.9b |

11.5ab |

11.7a |

11.9a |

11.3b |

11.8a |

11.6ab |

0.014 |

0.223 |

|

28 |

10.4b |

11.2a |

11.4a |

11.5a |

10.9ab |

11.3a |

11.3a |

0.006 |

0.237 |

|

56 |

9.7b |

10.6ab |

11.3a |

11.6a |

10.4ab |

10.9ab |

11.2a |

0.003 |

0.358 |

|

a, bMeans

with different letters within the same rows are significantly different

at the 5% level. |

|||||||||

At day 0 of storage time, the CP contents were not significantly different among the treatment (P>0.05). In general the CP contents of the water hyacinth silages in all the treatments were gradually reduced during the incubation. No significant difference (P>0.05) of CP content was found among the treatments at day 7. However, from day 14 to day 56 after ensiling it was significantly different (P<0.05) with lowest value of 9.10 % for the NA treatment. The result of present study was higher than that of 9.10 % reported by Lowilai et al. (1994). The treatments treated with molasses tended to be higher in CP content as compared to those treated ground maize or without additives from 28 to 56 days. It can be explained that adding molasses in water hyacinth silage as energy source increased lactic acid activity to drop rapidly pH, so further microbial fermentation was inhibited to decrease nutrient loss, especially protein. There was no significant difference among the treatments added with molasses levels. This was similar to the results reported by Nisa et al. (2008). The CP content of water hyacinth silage was higher than that of guinea grass silage found by Babayemi (2009) being from 4.9 to 7.2% at day 47 after ensiling.

|

Table 6: Effect of sugarcane molasses and ground maize levels as additives on NDF content (DM basis) of water hyacinth silage |

|||||||||

|

Incubated time (day) |

Treatment |

P |

ąSE |

||||||

|

NA |

M7.7 |

M11.5 |

M15.3 |

GM7.7 |

GM11.5 |

GM15.3 |

|||

|

0 |

63.2 |

62.6 |

63.3 |

61.8 |

63.1 |

62.7 |

62.4 |

0.704 |

0.917 |

|

7 |

62.9 |

62.3 |

63.0 |

61.9 |

62.8 |

62.5 |

62.3 |

0.748 |

0.738 |

|

14 |

61.9 |

62.0 |

63.0 |

61.9 |

61.4 |

61.8 |

62.1 |

0.682 |

0.868 |

|

28 |

59.9 |

60.0 |

62.3 |

60.6 |

59.9 |

61.0 |

61.8 |

0.230 |

1.095 |

|

56 |

57.8 |

59.2 |

60.5 |

59.7 |

58.8 |

59.1 |

59.7 |

0.250 |

0.953 |

|

NA: water hyacinth without

additives |

|||||||||

The NDF content of water hyacinth silage with additives and without additives was showed (Table 6). The NDF content of all treatments reduced slightly and gradually during incubation time and but not significantly different (P>0.05) among the treatments. The results in the study was higher than those reported by Lowilai et al (1994), however, lower than in report of 72.9 % by Baldwin et al. (1975). Silage made from water hyacinth was higher in NDF content than that from sweet potato vine stated by Kaya and Caliskan (2010) being from 27.5 to 36.3%.

|

Table 7: Effect of sugarcane molasses and ground maize levels as additives on physical characteristics of water hyacinth silage |

|||||||

|

Incubated time (day) |

Treatments |

||||||

|

NA |

7.7M |

11.5M |

15.3M |

7.7GM |

11.5GM |

15.3GM |

|

|

0 |

G - |

G PS |

G PS |

G PS |

G - |

G - |

G - |

|

7 |

G LSV |

YG LSV |

YG LPA |

LG PA |

YG LSV |

YG LSV |

YG LSV |

|

14 |

YG SV |

LY SV |

LY PA |

Y PA |

LY SV |

LY SV |

LY SV |

|

28 |

LY SV |

Y SV |

DY PA |

DY PA+ |

Y SV |

Y SV |

DY SV+ |

|

56 |

YB SV |

Y SV |

DY PA+ |

DY PA+ |

YB SV |

YB SV+ |

DY SV+ |

|

G: green, Y: yellow, B: brown, L: light, D: dark, PS: pleasant and sweet, SV: sour vinegar, PA: pleasantly acidic |

|||||||

At the day 0 all treatments had green color and the treatments treated with molasses has sweet smell. Light yellow to yellow color was observed in water hyacinth silage treated with molasses and ground maize at 14th day after ensiling (Table 7). The different yellow color was in accordance with the report of Kung and Shaver (2002) that when a green plant material that was ensiled producing yellow color, it can be classified as well made silage. The addition of molasses supported lactic acid bacteria activity, so silage had pleasant acidic. Babayemi (2009) also stated good silage had yellow color and pleasant smell. After 56 days of fermentation time, water hyacinth silages in all treatments had dark yellow to yellowish brown and heavily sour vinegar or acidic smell. The color and smell of the silage in the present study were similar to those reported by Nguyen Van Hiep (2008) when ensiling Kudzu with different molasses. By testing on feeding the silage to cattle, the study also indicated that silage added molasses at day 14 of incubation was easily acceptable by cattle.

Ensiling water hyacinth with additives as sugarcane molasses or ground maize decreased nutrient loss.

Silage made from water hyacinth treated with molasses level of 11.5 and 15.3% (DM basis) was good in term of color and smell and easily acceptable by cattle.

AOAC 1990 Official methods of analysis (15th edition). Washington, DC. Volume 1: 69-90.

Babayemi O J 2009 Silage quality, dry matter intake and digestibility by West African dwarf sheep of Guinea grass (Panicum maximum cv Ntchisi) harvested at 4 and 12 week regrowths. African Journal of Biotechnology Vol. 8 (16), pp. 3983-3988

Bagnal L O, Baldwin J A and Hentges J F 1974 Processing and storage of water hyacinth silage. Hyacinth Control Journal 12: 73-78.

Baldwin J A, J F Hentges, L O Bagnall and R L Shirley 1975 Comparison of Pangolagrass and Water Hyacinth Silages as diets of sheep. J Anim Sci 40:968-971

El-Serafy A M, Soliman H S H, Khattab H M, El-Ashry M A and Swidan F Z 1981 Dry matter intake and nutrients digestibility of water hyacinth hay, haylage and silage by buffalo steers. Indian Journal of Animal Science. 57 : 698-701.

Hentges J F, R E Salveson, R L Shirley and J E Moore 1972 Processes aquatic plants in cattle diets. J. Anim. Sci. 34:360

Kaya S and Mt ECaliskan 2010 Effects of molasses and ground wheat additions on the quality of groundnut, sweet potato, and Jerusalem artichoke tops silages. African Journal of Agricultural Research Vol. 5 (9), pp. 829-833, 4 May, 2010

Kung L, Shaver R 2002 Interpretation and use of silage fermenta-tion analyses reports. Dept. of Animal and Food Science, University of Delaware Newark, DE 19717.

Kusimeju K and Chizea FD 1992 Report on water hyacinth infestation of river Niger. Technical report submitted to Federal ministry of Science and technology Lagos, p. 13.

Lowilai P, K Kabata and C Okamoto 1994 Effects of rice bran and wheat bran on fermentation quality and chemical composition of water hyacinth silage J. Japan. Grassl. Sci. (3): 271-277

Mahala A G and I M Khalifa 2007 The Effect of Molasses Levels on Quality of Sorghum (Sorghum bicolor) Silage. Journal of Animal and Veterinary Sciences, 2: 43-46

Minitab 2000 Minitab reference manual release 13.20. Minitab Inc.

Nguyen Van Hiep, Hans Wiktorsson* and Ngo Van Man 2008 The effect of molasses on the quality of Kudzu silage and evaluation of feed intake and digestibility of diets supplemented with Kudzu silage or Kudzu hay by heifers. Livestock Research for Rural Development, Volume 20, Supplement, May 2008. http://www.lrrd.org/lrrd20/supplement/cont2005sup.htm

Nisa M, M A Shahzad, M Sarwar, N A Tauqir 2006 Influence of Additives and Fermentation Periods on Silage Characteristics, Chemical Composition, and In Situ Digestion Kinetics of Jambo Silage and Its Fodder in Nili Buffalo BullsTurk. J. Vet. Anim. Sci.2008; 32(2): 67-72

Ranjit N K and L Kung 2000 The effect of Lactobacillus buchheri, Lactobacillus plantarum or a chemical preservative on the fermentation and aerobic stability of corn silage. J. Dairy Sci., 83: 526-535.

Shiralipour A and Smith P H 1984 Conversion of biomass to methane gas. Biomass 6: 85-94.

Taylor K G 1969 The protein of water hyacinth (Eichhornia crassipes) and its potentian contribution to human nutrition. Un-published thesis, University of Florida, 51 pp

Van Soest P J, Robertson J B and Lewis B A 1991 Symposium: Carbohydrate methodology, metabolism and nutritional implications in dairy cattle: methods for dietary fiber, and non-starch polysaccharides in relation to animal nutrition. J. Dairy Sci. 74: 3585-3597.

Yakota H, J H Kim, T Okajima and M Ohshima 1992 Nutritional quality of wilted Napier grass ensiled with or