A carbon-negative model for production

of feed and fuel from biomass; experiences in Cambodia and

Colombia

Thomas R Preston

Finca Ecológica TOSOLY

Santander Sur, Colombia

trpreston@mekarn.org

Today, the extrasomatic energy used by people around the world is equal to the work of some 280 billion men. It is as if every man, woman, and child in the world had 50 slaves. In a technological society such as the United States, every person has more than 200 such "ghost slaves."

Abstract

There continues to be heated debate about the wisdom of the policies being promoted mainly but not only in rich countries to replace imported petroleum products with bio-fuels derived from biomass that are also the primary source of food for humans and feed for animals or from crops that displace food crops.

Ethanol is promoted as the replacement for transport fuel, and is derived mainly from maize and sugar cane,. Hundreds of ethanol distilleries are in operation and under construction. Distilleries that will use wheat and cassava are also in the pipeline. The main source of bio-fuel that can be used in diesel engines is the oil from the African oil palm, oilseed rape, soybeans and other oilseeds.

Indicative of the concern being felt in many quarters concerning development of fuel from crops that are the staple of the human diet, was the decision made recently by the President of Mexico who vetoed the growing of maize and sugar cane for biofuels production

The most vehement critics of the ethanol program are Professor

Tad W. Patzek of the Department of Civil and Environmental

Engineering, University of California and Professor David Pimentel

of the University of Cornell. The conclusions made by Patzek

(2007) in his presentation at the recentRound Table on Sustainable

Development of Biofuels, in Paris were: "to decrease all

automotive fuel use …. by up to 6 percent per year

….., while switching to rechargeable hybrid and all-electric

cars".

Professor Patzek recommended that the electricity should be

generated from direct use of solar energy in photovoltaic panels.

However, this technology is still extremely expensive. A 5 KWe

power supply requires an investment of over USD 30,000 or USD 6,000

per KWe. A related issue is that such systems offer few

opportunities of employment, especially in rural

areas.

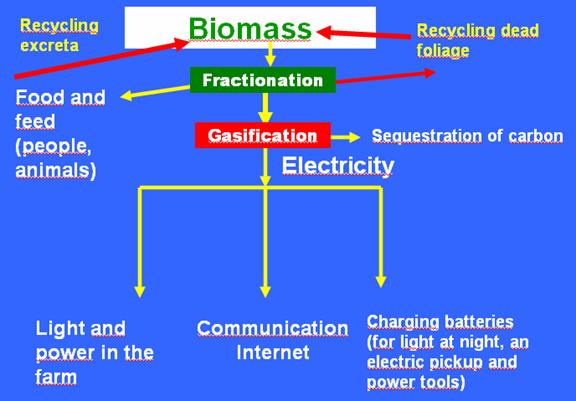

The alternative approach that is the subject of this

presentation is the generation of electricity as a by-product, or

associated product, of food/feed production. The concept underlying

this approach is that biomass consists of cell walls and cell

contents, the former acting as physical support structures for the

plant while the latter are composed of compounds that are mostly

edible by humans and or animals. Inedible cell wall biomass is

easily converted to a fuel gas by the process of gasification, the

gas in turn fuels internal combustion engines driving electrical

generators. The cell contents and related structures, such as tree

leaves, are used as animal feed.

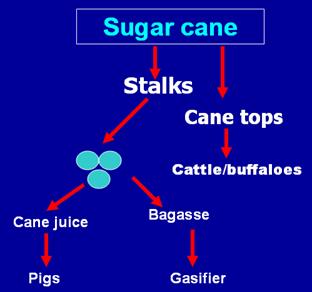

The model being implemented in Colombia is based around

production of sugar cane and forage trees. Sugar cane is separated

into soluble sugars (for animal feed or human food) and bagasse,

the residual fibrous biomass (feedstock for gasification), by

passing the cane stalks through a crushing machine. In the case of

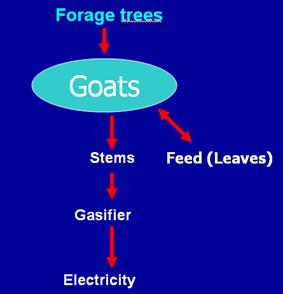

the forage trees, goats are introduced to partition the tree forage

into edible and non edible biomass. Goats naturally consume the

most nutritious parts of the tree (the leaves and bark) leaving as

residue the highly lignified stems and branches which serve as feed

stock for gasification.

This model is highly appropriate for decentralized, small-scale

production of food ,feed and feedstock for electricity in rural

areas. It also offers opportunities for sequestration of carbon in

the form of biochar - the solid residue high in carbon remaining

after gasification of the biomass. Long distance transport of

biomass (as to a conventional distillery or power plant) and its

associated high fuel cost is avoided, rural employment

opportunities are promoted for growing the biomass, and

availability of low-cost sources of electricity will facilitate

development of rural industry, including sale of electricity by

providing access points for charging the batteries of electric

vehicles..

Key words: bio-fuel Biochar, biomass, electricity, electric cars, ethanol, forage trees, goats, pyrolysis, rural development, sugar cane, fractionation

Introduction

Increasing prices and declining availability of fossil fuels, climate change and global resource depletion, are realities that will have a major impact on life styles and living standards throughout the world (Leng 2008). Oil prices will have the major impact on food supplies for two reasons: (i) the direct effect of the oil price on costs of inputs to agriculture (fertilizers, herbicides and other agricultural chemicals, machinery and the diesel and gasoline that fuels agricultural equipment); and (ii) the use of cropping land and related resources to grow bio-fuels to reduce dependency on those of fossil origin. Climate change is predicted to reduce crop yields especially in tropical areas and lower latitudes where poverty and inadequate nutrition are already major problems. Declining availability and increasing cost of mined sources of phosphorus and potash will result in reduced application of these fertilizers and hence declining yields.

It is estimated that some two thirds of the present 6.5 billion people on planet Earth receive their food supplies through the use of oil-derived inputs. The direct negative impact of declining availability of oil on food production, and the indirect impact of food crops being used as sources of biofuels, will negatively affect food supplies for people, especially the poor. Reduced availability of feed, or the high cost of feed for industrial animal production, will result in reduced animal protein availability to balance the nutrition of people largely consuming cereal based diets leading to both an increase in under-nutrition and mal-nutrition in the most resource-poor people Food inflation already exceeds the rate of inflation in non-food commodities, and is predicted to increase further as demand (the predicted 50% increase in the human world population) exceeds supply. Stocks of cereals are already at the lowest level for the last 20 years and continue to decline. The debate concerning the use of biomass for food or fuel (Brown 2007) merits careful analysis of the factors that are involved and identification of strategies to avoid the implied conflict.

Biomass as a source of food or fuel? What are the issues?

There are three major issues:

-

Should crops normally grown as sources of food / feed be used to make biofuel?

-

Is it feasible to produce enough biofuel (as ethanol or biodiesel) to replace existing sources of fossil fuel, especially for transport? If not what is the alternative strategy?

-

What is the way forward for livestock-based farming systems in a world faced with declining fossil fuel supplies, climate change and decline in all world resources, especially those used in agriculture.

-

Is it possible to support the largely urbanized populations in the changing agricultural environment

To be able to make a reasoned judgment on these issues, it is necessary to understand what are the sources of biofuels, what are the rates of conversion of these raw materials into final products, the economics of these processes, especially the EROI ((EROI is the energy that one obtains from an activity compared to the energy it took to generate that activity), and more importantly the implications for agriculture - and hence food production - of replacing fossil fuels with biofuels.

Sources of bio-fuels

The bio-fuels that are currently receiving most attention (and private investment / Government subsidies) are ethanol and biodiesel. This paper will endeavour to show that production of hydrogen-rich gas (producer gas) by gasification of fibrous biomass is a more appropriate pathway than either ethanol or biodiesel.

Ethanol

Ethanol is produced by yeast fermentation of sugars derived from biomass. At the present time the major substrates for ethanol production world wide are maize and sugar cane. Cassava roots and cereal grains, such as wheat and sorghum,are being used according to their availability in a particular regions. Conversion rates for these different feedstocks are defined by the stoichiometry of the fermentation process in which one molecule of hexose gives rise to 2 molecules of alcohol:

C6H5O6 à

2C2H5OH + 2CO2

Thus 182 g of hexose as starch or sucrose are needed to produce 92 g of ethanol, which translates into the approximate conversion rates shown in Table 1.

|

Table 1: Conversion of maize, cassava roots and sugar cane stalk into ethanol |

|

|

Feedstock |

kg biomass to produce 1 litre of anhydrous ethanol |

|

Maize1 |

2.6 |

|

Cassava2 |

5.45 |

|

Sugar cane2 |

14 |

|

1 Air-dry basis; 2 Fresh basis |

|

These feedstocks are traditionally sources of human food / animal feed, thus their use to produce biofuel results in (i) competition in the demand for these goods; and (ii) effects on food / feed prices according to the replacement value of ethanol for gasoline, which in turn is determined by current prices of fossil fuel.

The immediate result of the establishment of the subsidized ethanol industry has been major increases in the price of grains and political responses such as that by the President of Mexico in September 2007, when he promised to veto any intended legislation that would encourage the cultivation of maize and sugar cane for ethanol.

Biodiesel

The major sources of biodiesel are the broad acre oilseed crops

(soybean, rapeseed [canola in North America], sunflower, safflower

and sesame) and from fruit and special plant fruits such as the

African Oil Palm, Jatropha curcasand Castor bean (Ricinus

communis).

Apart from Castor bean and Jatropha which appear to be able to be produced on non cropping land, the same problem exists of competition between food and fuel.

Potential for gasoline and diesel to be replaced by bio-fuels

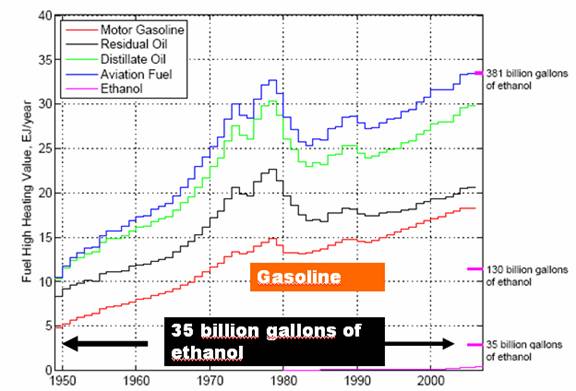

The second issue is the degree to which the present programs for biofuel production can replace the actual levels of consumption of the transport fuels - gasoline, LNG and diesel oil. Data for the USA show that even with the current target of 36 billion gallons of ethanol (which would require at a minimum 300 million tones of maize - the whole of the US crop - to be converted to ethanol), the potential replacement of gasoline alone is only of the order of 20% (Figure 1).

|

|

|

|

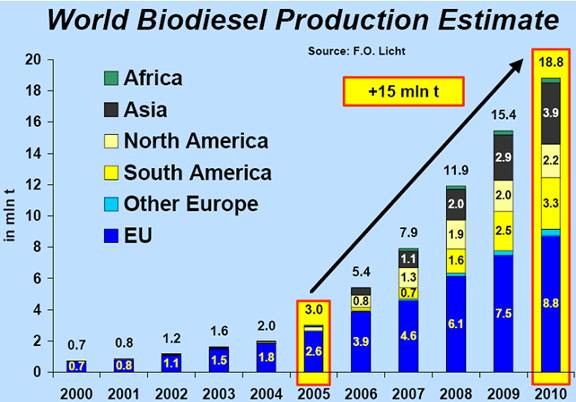

The situation with biodiesel is similar. Despite the rosy projections (Figure 2) made in 2005 of a fivefold increase in biodiesel production by the year 2010, the reality is one of uncertainly. Recent reports indicate that in Europe the majority of factories under construction will not be commissioned as their viability is doubtful because of high cost of raw materials, lack of incentives (Government subsidies!!) and even disincentives (proposed Government taxes).

|

|

|

|

In any event, the potential to replace existing usage of diesel derived from petroleum, with biodiesel derived from vegetative sources, is marginal and mirrors the case of ethanol described earlier. For example it was calculated that if all the cultivable area in the UK was planted with rape seed it would still replace only some 15% of actual usage (Table 2).

|

Table 2: Potential of biodiesel from rape seed to replace diesel oil in UK |

|

|

Annual diesel oil consumption |

37.5 million tonnes |

|

Rapeseed yield |

3.25 tonnes/ha |

|

Biodiesel from 1 tonne rapeseed |

415 kg |

|

Area to be planted in rapeseed to replace actual diesel oil consumption |

25.9 million ha |

|

Cultivable area available in UK |

5.7 million ha |

The conclusion by Patzek (2007), and many other analysts, is that the basic error is to pursue alternatives to liquid fuels, at least for ground transportation, as the potential to derive ethanol and biodiesel from biomass is less than 20% of projected needs and when all costs are calculated the net energy return on investment is negative. Although others see it differently(see Farrell et al 2006) there is a small margin between energy produced in ethanol and energy expenditure to obtain the feed stock, process the ethanol and deal with the pollution and soil erosion that arises from industrialized production . In contrast, there is sufficient energy from the sun provided it is captured mainly by solar panels, and from wind and wave power which has much lower energy demand for its production. However, the energy product from these sources is in the form of electricity, hence the proposed strategy of phased electrification of the automobile fleet and of mass transit systems (Patzek 2007) appears to be the most logical.

If electricity is the chosen replacement for petroleum, it can be shown that the potential contribution from biomass is much greater when it is converted to a combustible gas in a gasifier that if it is used as feedstock for ethanol. This is because the production of combustible gases by gasification is a well established technology (Chandrakant Turare 1997). Moreover, when these gases are used in internal combustion engines (or gas turbines) to produce electricity, there are other major benefits such as:

-

localization of the supply (in rural areas where the biomass is produced)

-

utilization at source (hence creating employment opportunities and giving comparative advantage to rural areas)

-

requires no inputs from fossil fuels once it has been constructed

-

creates opportunities for carbon sequestration

-

no conflict between food and fuel

Feed and fuel from biomass

Fractionation of the biomass

Biomass crops contain two distinct material sources the structural components and the sugars, starches, lipids and proteins in the tissues and fruits. The structural components of the cell walls serve as physical supporting structures, composed of cellulose and hemicelluloses cemented together by lignin . The logical use of these two groups of materials is for the former to be used as food for humans and / or feed for animals, and the latter as fuel.

Fractionation of plants into these two components can be done in a variety of ways, depending on the nature of the plant in question. Physical separation may be needed for crops such as sugar cane (Photo 1). For trees and shrubs, the leaves of which are used as animal feed, the animals themselves can do the separation (Photo 2).Where fruits are the main source of biofuels physical extraction is by pressure.

|

|

|

|

|

|

All tree crops provide fibrous residues (Photo 3) that can be used as feed stock in gasifiers: the stems and branches from coffee, coco and citrus trees; cuttings from bamboo used as construction material; branches from trees grown for timber.

|

|

|

|

The gasification process

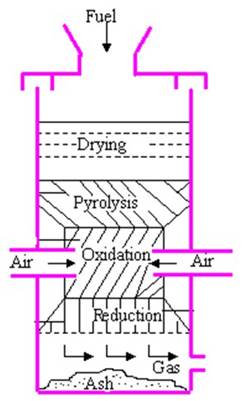

The essence of the gasification process is the conversion of solid carbon-based fuels into carbon monoxide and hydrogen by a thermo-chemical process in an air-sealed, closed chamber, under slightly reduced pressure (Figures 3 and 4).

|

|

|

|

Figure 3: Schematic design of a gasifier (Source:

Chandrakant Turare 1997) |

Figure 4: 9KW gasifier installed in CelAgrid, Cambodia (Source: T R

Preston) |

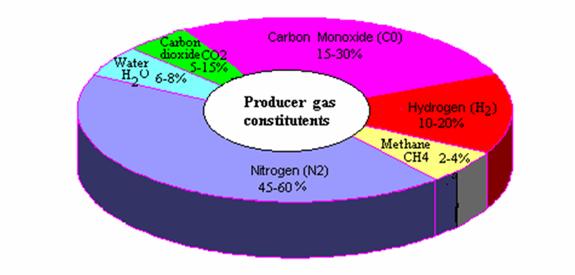

The biomass in the gasifier undergoes four processes; drying, pyrolysis, oxidation and reduction. Pyrolysis is the thermal decomposition of the dry biomass in the absence of oxygen. The products are bio-char (charcoal), liquids (oils) and gaseous products. The products of pyrolysis are then subjected to oxidation the end result of which is a combination of carbon, water and carbon dioxide. The carbon at high temperature reduces the water to hydrogen and the carbon dioxide to carbon monoxide. The final products are a gas the combustible part of which is hydrogen (10-20% by volume), carbon monoxide (15-30%) and methane (2-4%); the remainder is nitrogen and non-reacted carbon dioxide (Figure 5).

|

|

Figure 5: Range in composition of producer gas (from

Chandrakant Turare 1997) |

The outputs from a range of feed-stocks, despite a wide range in bulk density (128 to 346 g/litre) in a gasifier-engine-generator system in Cambodia were relatively similar (Table 3): 0.81 to 0.90 KWh of electricity and 0.11 to 0.14 kg residual char (including ash) per 1 kg of dry biomass.

|

Table 3:

Mean values for gasifier

characteristics using coconut shells-husks, cassava stems, mulberry

stems |

|||||||

|

|

Cassia |

Cassava |

Mulberry |

Coconut |

SEM |

Prob. |

|

|

Biomass DM, kg/test |

|

|

|

|

|

|

|

|

Initial |

36.7 |

32.3 |

33.7 |

34.4 |

1.3 |

0.21 |

|

|

Final |

4.93 |

1.90 |

0.00 |

3.07 |

2.19 |

0.49 |

|

|

Consumption |

36.9 |

35.1 |

40.0 |

36.4 |

2.9 |

0.69 |

|

|

Moisture, % |

14.0 |

13.3 |

15.7 |

14.0 |

1.4 |

0.69 |

|

|

Density, g/litre |

348a |

97.0c |

273b |

128c |

10.4 |

0.001 |

|

|

Duration, hr |

3.91 |

3.67 |

4.09 |

4.02 |

0.328 |

0.810 |

|

|

Output, kwh |

27.4 |

25.7 |

28.7 |

28.2 |

2.29 |

0.810 |

|

|

Conversion* |

1.23 |

1.18 |

1.18 |

1.11 |

0.044 |

0.42 |

|

|

Yield, kwh/kg DM biomass |

0.813 |

0.848 |

0.850 |

0.903 |

0.032 |

0.400 |

|

|

Efficiency# |

0.187 |

0.204 |

0.204 |

0.217 |

0.0082 |

0.170 |

|

|

Char, g/kg biomass DM |

109 |

128 |

109 |

137 |

16.5 |

0.58 |

|

|

* kg dry biomass/kwh |

|||||||

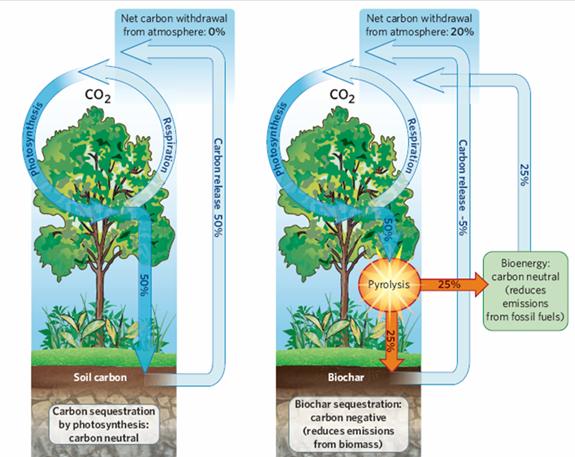

Carbon sequestration - a byproduct of gasification

Recent research (Figure 6) indicates that when biomass has been

subjected to pyrolysis (as in a gasifier), the reaction results in

a residual char of complex carbon compounds and contains most of

the minerals including phosphorus. This char is highly stable in

air and is not readily degraded further, when it is returned to

the soil. It is therefore

relatively inert

to the normal process of

oxidation. Lehman et al (2007) estimated that the net withdrawal

of carbon from the atmosphere by this process could be as much as

20% of the total interchange of carbon in photosynthesis and

subsequent oxidation.

The data in Table 3 indicate that some 10% of the original biomass (DM basis) added to the gasifier is produced in the form of bio-char and ash. Assuming that the ash content of this material is about 10% then it can be calculated that for every 1 KWh of electricity produced by gasification there is the potential for a net sequestration of 1 kg of carbon (equivalent to 3.3 kg of carbon dioxide). Taking the proposal from Lehman et al (2007) of a probable price of USD 37/tonne of avoided carbon dioxide emissions, then the value of the sequestered carbon in a gasifier power system would be USD 0.11 for each KWh of electricity that is produced. If the feed-stock is sugar cane bagasse then the potential value of the sequestered carbon dioxide is an extra income of USD 16.50/tonneof sugar cane.

|

Figure 6: Carbon sequestration from biomass by pyrolysis (gasification) (from Lehman 2007) |

Ethanol or producer gas from biomass

Proponents of ethanol argue that the conflict between food and fuel posed by use of current technology will be avoided in 2nd generation ethanol production systems, which will be based on use of fibrous, non-edible biomass as feedstock. Apart from the fact that there is as yet no commercially viable system for production of ethanol from fibrous biomass, the results from the pilot facility established by IOGEN in Canada, as analysed by Patzek (2007), are far from encouraging.

The principal steps in the process of making ethanol from fibrous biomass are:

-

Reduce the particle size of the biomass

-

Add water to give about 10% dry matter in the biomass slurry

-

Add sulphuric acid (or NaOH) and heat to solubilise the lignin and expose the cellulose and hemicelluloses

-

Add enzymes to hydrolyse the exposed cellulose and hemicelluloses to C6 and C5 sugars

-

Add genetically modified yeasts to ferment the C6 and C5 sugars to ethanol (Normal yeast does not ferment the 5-carbon sugars, so genetically modified yeast strains are used).

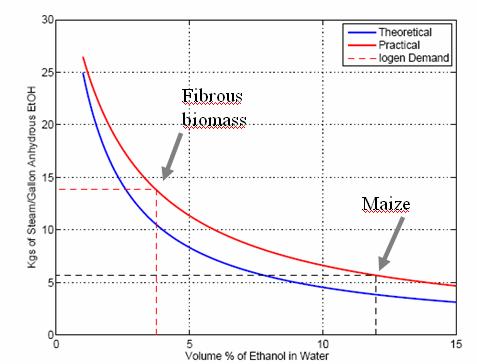

Patzek (2007) contends that the main problem lies in the characteristics of the final fermentation, as apparently the maximum concentration of ethanol that can be achieved in the end fermentative water mix is 4 to 5%, much less than the concentration of 11 to 12% reached by conventional yeast fermentation of hexose sugars from maize (Figure 7). As a result, much more energy is needed in the distillation process to remove the water.

|

|

|

|

However, the main criticism is that production of ethanol by fermentation of hydrolyzed biomass appears to be much less efficient than gasification, especially when the required end product is electricity (Table 4).

When ethanol is the chosen pathway:

-

additional energy is needed to grind the biomass and then heat it during the process of separating the lignin from the cellulose and hemicelluloses, and finally to distill the ethanol

-

chemicals are needed to solubilise the lignin

-

enzymes are needed for the hydrolysis of the cellulose and hemicelluloses

-

genetically modified yeast strains are needed to ferment the C5 sugars

-

Energy is needed to concentrate the ethanol and the ethanol nust be transported to sites where it is to be used

|

Table 4: Inputs and outputs when dry biomass is fermented to make ethanol or reacted in a gasifier |

||

|

System |

Ethanol |

Gasification |

|

Inputs |

||

|

Dry Biomass, kg |

1 |

1 |

|

Extra energy |

¿ |

None |

|

Chemicals |

¿ |

None |

|

Enzymes |

¿ |

None |

|

Outputs |

|

|

|

Ethanol, litres |

0.18# |

|

|

Electric power, kwh |

0.4## |

0.83### |

|

Bio-char, kg |

None |

0.09### |

|

Scale of operation |

Large |

Localized |

|

# From Badger 2002; ## Assumed that 1 litre of ethanol in an IC engine produces 3.5 kwh; ### From Miech Phalla and Preston 2005 |

||

By contrast, in the gasification process:

-

the transformation energy is provided by the partial oxidation of the biomass

-

the system is carbon negative as part of the carbon is returned to the soil as bio-char

-

the gasification system can be operated at all levels of scale whereas biomass ethanol is centralized and large scale with considerable costs for the transport of the biomass

Net primary productivity (NPP)

NPP is the total amount of plant growth used to build stems,

leaves and roots generated each year and quantified as mass of

carbon. If biomass is to be increasingly used as the source of food

/ feed, fuel, construction material, soil carbon for microbial

oxidation and medium for sequestration of carbon, then it is a

logical strategy to identify and grow those plants that have

maximum NPP.

|

|

|

|

Figure 8: Net biomass productivity in tropical and

temperate ecosystems (Kormondy 1969) |

Figure 9: Net biomass productivity of selected ecosystems

in USA (from Patzek 2007) |

Kormondy (1969) drew attention to the greater productivity of

ecosystems in tropical compared with temperate latitudes (Figure

8). Perennial crops and forests were more productive than annual

crops in both regions, the difference being more pronounced in the

tropics. Data for the USA (with most of the land area in temperate

latitudes) also show forest to be superior to (mostly annual) crops

with markedly low productivity for land managed as pasture (Figure

9). It is obvious from these data that perennial crops and trees

are the most appropriate ecosystems for maximizing biomass

production. At the same time they are more effective sinks for

carbon, both above and below ground), than annual crops the

management of which inevitably results in varying degrees of

disturbance of the soil ecosystems and resultant oxidation of

carbon.

Biomass as food/fuel and recycling

"If all mass must stay on the Earth, all her households must

recycle everything; otherwise

Models for small-farm scale production of feed/food and energy

The systems presently being practiced in the TOSOLY ecological farm in Colombia (http://www.utafoundation.org) are focused on semi-perennial sugar cane (Figure 10) and perennial forage trees with recycling of all wastes (Figure 11).

In the sugar cane component of the model, the products are:

-

raw sugar cane juice, which is the energy source for pigs

-

cane tops (leaves and growing point) which is the energy source for cattle and buffaloes

-

bagasse which is used as fuel/substrate for the gasifier

-

trash (dead leaves) which is returned to the soil as a source of organic matter

|

|

|

|

|

|

The forage tree component comprises a range of trees (Tithonia diversifolia, mulberry [Morus albus] and Erythrina poeppigiana) which are the basal diet of goats and sources of protein for cattle. As indicated in Photo 2, the goats selectively consume the leaves (and in some cases the bark) leaving the woody stems as fuel for the gasifier.

The overall farm model (Figure 12) shows the strategy for achieving both food and energy security.

|

|

|

|

Conclusions

-

The integrated farming system, using highly productive sources of biomass (sugar cane and tree crops) that are fractionated into food/feed and fuel, are highly appropriate for decentralized, small-scale production of electricity in rural areas without compromising food / feed production.

-

The model offers opportunities for sequestration of carbon in the form of biochar - the solid residue remaining after gasification of the fibrous biomass.

-

Long distance transport of biomass (as to a conventional distillery or power plant) is avoided, rural employment opportunities are promoted for growing the biomass, and availability of low-cost sources of electricity will facilitate development of rural industry, including access points for charging the batteries of electric vehicles.

The bottom line

Inexpensive fossil fuel facilitated the intensification of live stock production. The consequences were artificially cheap food, especially of animal origin, pollution because of the accumulation of animal excreta and the almost complete disappearance of small scale "family farms", particularly in rich countries. The imminent decline in availability of this resource should be the signal for a return to small scale farming which will give comparative advantages to the technologies described in this paper.

References

Badger P C 2002 Trends in new crops and new uses, Chapter. Ethanol from Cellulose: A General Review, pp 17 - 21, ASHS Press, Alexandria, VA. http://www.hort.purdue.edu/newcrop/ncnu02/v5-017.html

Botero R y Preston T R 1987

Biodigestor de bajo costo

para la producción de combustible y fertilizante a partir de

excretas: Manual para su instalación, operación y

utilización. CIPAV, Cali, Colombia http://www.utafoundation.org/publications/botero&preston.pdf

Bui Xuan An, Preston T R and Dolberg F

1997 The introduction of low-cost polyethylene tube

biodigesters on small scale farms in Vietnam. Livestock Research

for Rural Development. (20) 1. http://www.cipav.org.co/lrrd/lrrd9/2/an92.htm

Brown L R 2007 Plan B 2.0: Rescuing a Planet Under Stress

and a Civilization in Trouble.

Earth Policy Institute, USA http://www.earth-policy.org/Books/PB3/index.htm

Chandrakant Turare 1997 Biomass Gasification Technology

and Utilization. ARTES Institute, University of Flensburge,

Germanyhttp://members.tripod.com/%7ecturare/bio.htm

Duong Nguyen Khang and Le Minh Tuan 2002 Transferring

the low cost plastic film biodigester technology to farmers.

Proceedings

Biodigester Workshop March 2002. Hanoi, Vietnam http://www.mekarn.org/procbiod/khang2a.htm

Farrell A E, Plevin R J, Turner B T, Jones A D,

O'Hare M and Kammen D M 2006

Kormondy E J 1969 Concepts of ecology. Prentice-Hall; Engelwood Cliffs NJ, USA

Lehmann J 2007 A handful of carbon. Commentary. Nature Volume 447, 10 May 2007

Leng R A 2008 Decline in available world resources;

implications for livestock production systems in Asia. Livestock

Research for Rural Development. (20) 1. httm://cipav.org.co/lrrd/lrrd20/1/leng.htm

Licht F O 2005 World Ethanol and Biofuels Report. Volume

3., Tunbridge Wells, United Kingdom.

Miech Phalla and Preston T R 2005. Evaluating selected

inedible fibrous crop residues as feedstock for gasification. MSc

Thesis. MEKARN-SLU

Patzek T W 2007 How can we outlive our way of life; Paper prepared for the 20th Round Table on Sustainable Development of Biofuels: Is the Cure Worse than the Disease? OECD Headquarters, Chˆateau de la Muette, Paris, 11-12 September 2007 http://petroleum.berkeley.edu/papers/Biofuels/OECDSept102007TWPatzek.pdf