|

| Figure 1. IMO4 is the result of composting chicken manure with the mixture of native microorganism (NM)) |

|

Livestock-Based Farming Systems, Renewable Resources and the Environment |

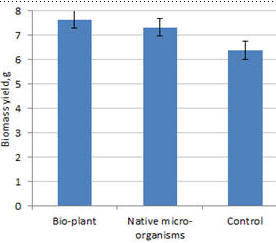

A biotest with Brassia juncea L. vegetable as a test plant was used to evaluate chicken manure composted with native microorganism (NM), a commercial inoculum (Bio-plant) and fresh water (control).

Plant height, number of leaves and harvested yield were not different between “NM” and “Bio-plant” compost and tended to be higher (P=0.09) than for the control. However, the mixture of native microorganisms (NM) was easy to make, was stable and low cost in comparison with the commercial Bio-plant product. The populations of micro-organisms were much higher in compost inoculated with both "NM" and "Bio-plant" compared with the control. The yield of Brassica juncea L increased curvilinearly with level of application of the "NM" compost with the peak occurring at 30 tonnes/ha of compost.

According to FAO, Vietnam ranked the thirteen in amount of chicken in the world. In 2007 the national poultry population was 254.6 million (Statistical Yearbook of Viet Nam, 2007), including 185.2 million chickens (72.8 percent) and 68.9 x 106 water-birds (27.2 percent), it also generated as by products large amounts of manure led to serious environmental pollution because of lack of cost-effective technologies for processing poultry manure and the inappropriate disposal of waste.

The use of animal manures to improve soil fertility (Kapkiyai et al 1999), increase soil organic matter (Kaur et al 2008), plant growth (Mhlontlo et al 2007; Hao et al 2007) and soil properties (Maerere aet al 2000) is well established in literature. It also is a valuable resource on an organic farm. It has also been reported that animal manure applied to soils have high soil microorganism, P, K, Ca, Mg and NO3 than soils to which inorganic fertilizers have been applied (Edmeades 2003; Herencia et al 2007). However the quality of manures depends on composting process because composting is commonly used to improve the properties of manures for organic farming.

Indigenous micro-organism (IMO) uses local natural microbe potential (Han and Koyama 1997; Rodríguez et al 2011). Using of indigenous micro-organisms not only makes soil and plants healthy but also prevents diseases (Han Kyu Cho 2009). The Vietnam Productivity Center (VPC) transferred this technology successfully from Korea on rice and some kinds of vegetable and showed that using microbial organic fertilizer could replace 50% of chemical fertilizer while crop yield remained with improved safety and low NO3- content in products.

This paper is intended to evaluate the potential of the mixture of natural microorganism to compost chicken manure in comparison with commercial product as a means of animal waste management and utilization on Brassica juncea. L cultivation.

The research was carried out at Centre for Organic Agriculture Promotion and Studies, Hanoi University of Agriculture, Vietnam from January to December 2011.

The experiment was arranged in Random complete block design (RCBD).

The number of experiment treatments is 3:

- Prepare 3 inches of steamed rice fill the wooden box, cover the box with white paper towel so that air can pass into the container

- Bury the box in the soil at least 2 inches deep (where has a lot of humus litter around because we will collect the most healthy colony of micro-organisms)

- Leave the box undisturbed for a minimum of 4-5 days, check to see whether the moist rice is covered with coloured mould

- Gradually add an amount of brown sugar equal to the weight of the rice mass, hand-knead until the material has the consistency of gooey molasses (NM)

- Store in the pot in a cool area for 7 days. This will allow the mixture to ferment

- Add a small amount of water to the fermented rice mixture in a 1/500 ratio. Then, slowly blend in rice bran (50 kg) run until mixture is of semi-moist but not wet consistency (roughly 65-70% moisture) (IMO2)

- Place a mound of the mixture on a soil surface and cover it the straw, protecting it from sunlight. Monitor internal temperature of the pile not to exceed 500C. When the external surface of the pile has white mould, internal temperature will stabilize, the fermentation process is finished. Using them to compost manure.

Dry chicken manure used in this work was obtained by chicken farm at household in Gia Lam district. The characteristics of manure are reported in Table 1.

|

Table 1: Chemical properties of chicken manure before composting |

|||||||||||

|

pH |

Moisture content % |

Organic matter % |

C/N |

Total nitrogen % |

Total phosphate % |

Total potassium % |

Ca % |

Mg % |

Cu mg/kg |

Zn mg/kg |

Pb mg/kg |

|

8.6 |

11.7 |

18.8 |

17.9 |

0.63 |

0.95 |

0.52 |

1.82 |

0.61 |

5.65 |

70.1 |

6.09 |

Two hundred and fifty kilograms of chicken manure (included rice husk), 5 kilograms (2%) of rice straw with 5cm long (Gray et al 1971; Rabbani et al 1983), 25kg soil and 12.5 kilograms of rice bran were mixed together into pile (Figure 1)..

|

| Figure 1. IMO4 is the result of composting chicken manure with the mixture of native microorganism (NM)) |

Each product was diluted according to instructions, and then spray into the pile in order that heap got 40%-50% moisture content wet weight. After that, the piles were coved by black polyethylene. The process of composting was studied using aerobic composting, rotated by hand 2 times in composting process.

Four temperature sensors were introduced in 5 different points of the compost pile and measured every 2 days in composting period.

In all experiments, sample was taken for analysis at the end of the composting process (when the temperature reached a constant value): pH, moisture content, C/N, nitrogen, phosphate, potassium, CaO, MgO, Cu, Pb, Zn, Microbiological indicator. Methods for compost manure characteristics determination:

- Total nitrogen was determined by Kjeldahl method (Bremner 1996)

- Total phosphorus was determined by Ascorbic Acid method (Kuo 1996)

- Total K: determine the K concentration by flame photometric method (Vadzenin 1975)

- OM: Walkley-Back method (Nelson et al 1996)

- pH: pH met machine

- Ca++, Mg++: were measured by titration with Trilon B

- Cu, Pb, Zn: Spectrophotometric atomic absorption (AAS) method

- Compost manure microbial count by Agamedium method (Nguyen Xuan Thanh 2007)

Basal statistical parameters were calculated by Excel Software and Analysis of Variance (ANOVA) for experimental data is done by IRRISTAT 4.0.

The experiment was conducted at Center for Organic Agriculture Promotion and Studies, HUA during the year of 2011.

The experiment was laid out in randomized complete block design (RCBD) with four applications of levels of 20 ton/ha compost fertilizer

The compost was broadcast on the box before sowing. Area of each box was 0.12m2, transplanted 12 plants/box.

Three plants in each box were randomly selected and tagged for recording plant height, number of leaves, individual yield and harvested yield.

The data were statistically analyzed with ANOVA by IRRISTAT 4.0 software.

The experiment was conducted at Center of Organic Agriculture Promotion and Studies, HUA during the year of 2011

The experiment was laid out in randomized complete block design with three applications of four levels of “NM” compost (1, 2, 3, 4 kg/m2). The compost was broadcast on the box before sowing. Area of each box (plot) was 0.24m2, transplanted 24plants/box. Boxes received identical cultural treatments in terms of cultivation, seed rate, sowing method, micro-organic fertilizers, and disease control. Biological insecticides were employed against different insects, diseases during the course of study.

Five plants in each box were randomly selected and tagged for recording plant height, number of leave, individual yield and harvested yield.

The data were statistically analyzed with ANOVA by IRRISTAT 4.0 software.

An indicator of the amount of biological activity taking place within the compost pile was obtained by measuring temperatures daily throughout the active decomposition and curing stages. From the fig 1, the temperature rose rapidly during the first 15 days, reached a peak at about day 15 with over 500C. The composting process reached the maximum temperature of 52.40C after 15 days in Bio-plant products, whereas NM reached lower maximum temperatures (51.90C after 15 days), then reduced quickly until it returned to about ambient temperature with 36.40C after 35 days.

Judging from temperature profile in Figure 2, there were no significant differences in the temperature regime among 3 treatments in experiment. Manure composting proceeded primarily within the temperature range of 32-530C during the active decomposition stage, which is the optimum range for biological activity (Merkel 1981).

|

|

|

Figure 2: The change of temperature of compost manure pile |

The analysis showed that the pH values of three compost treatments ranged from 8.93 to 9.16 (before composting pH value was 8.6). Following researches, poultry manure raises pH because chicken feed contains calcium carbonate, which ends up in the chicken feces. Especially, if pH reaches 9, nitrogen is converted to ammonia like Bio-plant treatment.

|

Table 2: Characteristics of manure after finishing compost (final product) |

||||||

|

Treatments |

Fresh water(Control) |

NM |

Bio-plant |

Prob |

CV (%) |

LSD0.05 |

|

pH |

8.94 |

8.93 |

9.16 |

|

|

|

|

Moisture content (%) |

11.3b |

11.7ab |

12.6a |

0.094 |

5.2 |

1.23 |

|

Organic matter (%) |

19.8c |

22.4b |

25.4a |

< 0.001 |

2.6 |

1.17 |

|

C/N |

16.6a |

16.3a |

16.0a |

0.383 |

2.8 |

0.92 |

|

Total nitrogen (%) |

0.79b |

0.85ab |

0.92a |

0.101 |

6.8 |

0.12 |

|

Total phosphate (%) |

1.94 |

1.94 |

1.93 |

|

|

|

|

Total potassium (%) |

0.77 |

0.94 |

0.81 |

|

|

|

|

Ca (%) |

1.87 |

1.94 |

2.01 |

|

|

|

|

Mg (%) |

0.56 |

0.67 |

0.73 |

|

|

|

|

Cu (mg/kg) |

5.33 |

5.72 |

6.84 |

|

|

|

|

Zn (mg/kg) |

71.6 |

69.0 |

69.2 |

|

|

|

|

Pb (mg/kg) |

5.66 |

5.95 |

8.64 |

|

|

|

|

abc Means in the same row without letter are different at P = 0.05 |

||||||

Moisture appeared to be low (11.3%-12.6 %) in comparison with the level of 40-60% commonly adopted for the aerobic composting, because at the initial stage it was hot and dry and chicken manure had a lot of rice husk made it difficulty in absorbing water. After composting, moisture content reduced as a result of evaporation, and temperature rise of the compost pile.

Organic matter increased slightly compared with that in before compost. OM content of “Bio-plant” compost got the highest value with 25.4%, followed by NM with 22.4%. They met requirement standard of composting manure [California Dept 2004]

C/N is one of the main characteristics that describe the composting process. The generally accepted optimum range of C/N ratio for composting is 25:1-30:1 which ensures that carbon and nitrogen are present in adequate proportions for microbial growth and decomposition of waste (Bishop et al 1983, Gotaas 1956). The low C/N ratio of the initial manure was 17.9 (depends on the type of beddings used in the coop) which can lead to rapid decomposition, possible accompanied by an increase loss of the excess nitrogen through ammonia volatilization (Bishop et al 1983; Gaur 1980). The final C/N ratio of about 10 is reached in the composting stabilization (Haug 1980). The results showed that C/N ratio reduced after composting, C/N ratio of NM, Bio-plant and control treatments were 16.3, 16.0 and 16.6 respectively. It can be accepted to stabilize composting (Saviozzi et al 1987).

The end of composting manure process increased the content of total Nitrogen, total potassium and total phosphorus because of addition compost materials like rice bran, soil… In three treatments, Bio-plant appeared to be the highest values in total N, total P2O5, total K2O with 0.92, 1.93, 0.81; following by IMO with 0.85, 1.94, 0.94 respectively.

The value of using animal manure compost can be affected by the presence of heavy metals (Cu, Zn, Pb) at the final product. The results are shown in table 2. Content of heavy metals was increased slightly, was suitable for the result of Wang et al 2009, among them Bio-plant rose biggest. However heavy metals were detected in the manure compost, the majority was present in relatively low concentrations which are unlikely to exert any significant toxicological effects on plant growth and are still well within acceptable level for solid-waste compost (Lutz 1984).

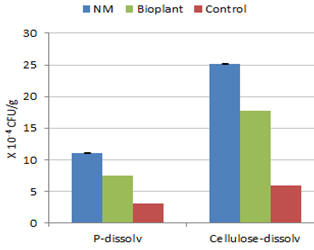

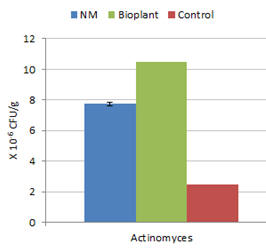

Decomposition of manure is brought about by biological activity of living micro-organism which utilize carbon as a source of energy and nitrogen for protein synthesis in order to maintain life, growth and multiplication (Gotaas 1956). The results of micro-organism analysis (Table 3; Figures 3 and 4) indicated that the populations of total useful micro-organism ranged from 2.00 x 108CFU/g to 10.8 x 108CFU/g, Bio-plant got the highest value with 10.8 x 108CFU/g. Aerobes/Anaerobes ratio in three treatments were greater than 10/1. However, populations of phosphorus-solving bacteria and Cellulose-solving bacteria of “NM” compost were bigger than Bio-plant with 11.0 x 104CFU/g and 25.2 x 104CFU/g; following by Bio-plant with 7.51 x 104CFU/g and 17.8 x 104CFU/g respectively. In general, treatments has no significant difference in population of micro-organism, some parameters were within acceptable levels for compost manure (California Dept 2004)

|

Table 3: Microbiological density of final compost |

||||||

|

Measurements |

Unit |

Control |

NM |

Bio-plant |

Prob |

LSD0.05 |

|

Total microorganisms |

X 108CFU/g |

2.00c |

6.68b |

10.8a |

<0.001 |

0.74 |

|

Total Aerobic microorganism |

X 108CFU/g |

1.85 |

6.48 |

10.7 |

|

|

|

Total fungi |

X 105CFU/g |

11.5 |

48.4 |

53.4 |

|

|

|

Total Actinomycetes |

X 106FU/g |

2.50 |

7.74 |

10.5 |

|

|

|

Phosphorus-solving bacteria |

X 104CFU/g |

3.05c |

11.0a |

7.5b |

<0.001 |

0.48 |

|

Cellulose-solving bacteria |

X 104CFU/g |

6c |

25.2a |

17.8b |

<0.001 |

0.95 |

|

abc Means in the same row without letter are different at P = 0.05 |

||||||

|

|

|

Figure 3. Effect of inoculation with "native" micro-organisms on P-dissolv, Cellulose-dissolv population |

Figure 4. Effect of inoculation with " native" micro-organisms on Actinomyces population |

There was no significant difference between application “NM” compost and “Bio-plant” compost in growth yield of vegetable (Table 4; Figures 5 and 6). However relationship between height of vegetable and the fresh matter yield of the green part (biomass) of “NM” compost was close with R2 = 0.91, much higher than that of “Bio-plant” compost with R2 = 0.78.

|

Table 4: Effect of different composts to growth yield of vegetable after 25 days |

||||

|

Treatment |

Harvest plant height (cm) |

Number of leaves |

Individual yield (g/plant) |

Harvested yield (g/0.12m2) |

|

“NM” compost |

17.9a |

5.82a |

7.34 |

88a |

|

“Bio-plant” compost |

18.5a |

5.91a |

7.62 |

91.5a |

|

“Fresh water” compost |

16.0b |

5.48b |

6.4 |

76.6b |

|

Prob |

0.01 |

0.001 |

|

0.009 |

|

LSD0.05 |

1.38 |

0.12 |

|

7.88 |

|

abc Means in the same column without letter are different at P = 0.05 |

||||

|

|

| Figure 5. Effect on biomass yield of Brassica spp of fertilizing with compost made with natural micro-organisms, a commercial inoculum (Bio-plant) or non-inoculated compost (Control) | Figure 6. Relationship between height plant and and biomass of green parts when application was "NM" compost |

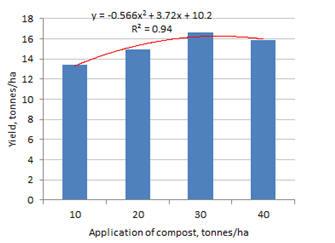

There was clear difference in plant height, number of leaves and harvested yield parameter of vegetable of four treatments when application “NM” compost (Table 6). Treatment 3kg/m2 had the highest harvested yield value with 399g/0.24m2. When increasing the rate of compost chicken manure with 4kg/m2 the harvested yield indicator had a decline trend, this may be due to high CO32- content (Mokolobate 2001; Cooper and Warman 1997; Materechera and Mkhabela 2008).

Based on the above results, an attempt was made to obtain a mathematical correlation between harvested yield and level of compost (Figure 7). Correlation factor (R2) around 0.94 demonstrated level of compost and harvested yield having close relation.

|

Table 6: Effect of different levels of “NM” compost to vegetable growth |

||||

|

Treatment |

Harvest plant height (cm) |

Number of leaves |

Individual yield (g/plant) |

Harvested yield (g/0.24m2) |

|

1kg/m2 |

23.7c |

10.0d |

13.4 |

323d |

|

2kg/m2 |

26.5b |

10.8c |

15.0 |

359c |

|

3kg/m2 |

30.0a |

12.0a |

16.6 |

399a |

|

4kg/m2 |

28.2ab |

11.4b |

15.8 |

380b |

|

Prob |

0.003 |

0.001 |

|

< 0.001 |

|

LSD0.05 |

2.18 |

0.58 |

|

14.2 |

|

abc Means in the same column without letter are different at P = 0.05 |

||||

|

| Figure 7. Effect of level of application "NM" compost on yield of Brassia juncea |

Beside, we calculated economical efficiency between made “NM” product and Bio-plant product. The results showed that total cost of making “NM” was lower than that of Bio-plant, especially amount of “NM” product made much volume in comparison with Bio-plant (Table 5). From the results of Experiment number 1 and 2, we realized chicken manure was composted by “NM” had lower cost than that of “Bio-plant” product.

|

Table 5: Cost of using NM product and Bio-plant |

||

|

Materials |

NM |

Bio-plant |

|

Total costs (Thousand VND) |

175,000 |

200,000 |

|

Rice |

40,000 |

|

|

Sugar |

65,000 |

|

|

Other costs |

70,000 |

|

|

Amount of concentrated solution made (liters) |

2 |

0.2 |

|

Dilute ratio |

1/500 |

1/2000 |

|

Total solution (litter) |

1000 |

400 |

The account of economic effect of applying different “NM” compost was checked whether it can increase economical efficiency (table 7). The results showed that dose of 3kg/m2 had the highest net return value with 31486 VND/m2.

|

Table 7: Economical effect of applying different levels of “NM” compost (VND/m2) |

|||

|

Treatments |

Total income |

Total cost |

Net return |

|

1kg/m2 (10 tonnes/ha) |

36028 |

11550 |

24478 |

|

2kg/m2 (20 tonnes/ha ) |

40532 |

12550 |

27982 |

|

3kg/m2 (30 tonnes/ha ) |

45036 |

13550 |

31486 |

|

4kg/m2 (40 tonnes/ha ) |

42784 |

14550 |

28234 |

The ingredients, the populations of micro-organism were higher in compost inoculated with “NM” and “Bio-plant” than that of control.

Growth yield of Brassica juncea L. was no significant difference when application “NM” and “Bio-plant” compost. However composting with the mixture of native micro-organism was easier to make, more stable with each local and lower cost in comparison with the commercial Bio-plant product.

The level of 3kg/m2 (equivalent with 30 tonnes/ha) of “NM” compost got the highest yield value with close relationship (R2 = 0.94).

Bishop P L and Godfrey C 1983 Nitrogen transformations during sludge composting. J. BioCycle, 24 (4): 34

California Department of Resources Recycling and Recovery 2004 Compost quality standards. From: http://calrecycle.ca.gov/Organics/Products/Quality/CQStandards.htm

Duc N V and Long T 2008 Poultry production systems in Vietnam. GCP/RAS/228/GER Working Paper No. 4. Rome. From: http://www.fao.org/docrep/013/al693e/al693e00.pdf

Hao X Y and Chang C 2002 Effect of 25 annual cattle manure applications on soluble and exchangeable cations in soil. Soil SCi. 167, 126-134.

Haug R T 1993 The practical Handbook of Compost Engineering. Lewis Publishers, Boca Raton

Hoon Park and DuPonte M W 2008 How to cultivate Indigenous microorganism. Biotechnology Aug.2008. From: http://www.ctahr.hawaii.edu/oc/freepubs/pdf/BIO-9.pdf

Kapkiyai J J, Karanjia N K, Qureshi J N, Smithson P C and Woomer P L 1999 Soil organic matter and nutrient dynamics in Kenya nitisol under long-term fertilizer and organic input management. Soil Biol. Biochem. 31, 17773-1782.

Kaur T, Brar B S and Dhillon N S 2008 Soil organic matter dynamics as affected by long term use of organic and inorganic fertilizers under maize-wheat cropping system. Nutr.Cycl.Agroecosyst.81, 59-69.

Lutz W 1984 Austria’s quality requirements for solid waste compost. J.BioCycle, 25(5): 42

Maerere A P, Kimbi G G and Nonga D L M 2001 Comparative effectiveness of animal manures on soil chemical properties, yield and root growth of amarathus (Amarathus cruentus L.). Afr. J. Sci. Technol. 1 (4), 14-21.

Materechera S A and Mkhabela T S 2008 The effectiveness of lime, chicken manure and leaf litter ash in ameliorating acidity in a soil previously under black wattle (Acacia mearnsii) plantation. Bioesour. Technol. 85, 9-16.

Merkel J A 1981. Managing Livestocks Wastes. A VI Publishing Co. Inc., Connecticut, p.334.

Mhlontlo S, Muchaonyerwa P and Mnkeni P N S 2007 Effects of sheep kraal manure on growth, dry matter yield and leaf nutrient composition of a local amaranthus accession in the central region of the Eastern Cape Province, South Africa. Water SA 33 (3), 363-368.

Pham Tien Dung and Yka Nin H’dok 2009. Microbial organic fertilizer application for safe coffee production at Daklak, Vietnam. J.ISSAAS Vol.15 No.1: 22-31 (2009).

Rodríguez L, Salazar P and Preston T R 2011 Effect of a culture of “native” micro-organisms, biochar and biodigester effluent on the growth of maize in acid soils. Livestock Research for Rural Development. Volume 23, Article #223. http://www.lrrd.org/lrrd23/10/rodr23223.htm