|

|

|

Photo 1: Compost pile |

|

Livestock-Based Farming Systems, Renewable Resources and the Environment |

Citation |

For many centuries, composting has been used as a mean to recycling organic mater back into the soil to improve soil instructure and fertility. The composting process has received much attention in recent years because of pollution concerns and the search for effective methods for treating animal waste. Nowadays, the pig industry faces increasing problem from piggery waste, especially pig manure.

This project provides information on use of aerobic composting method for the treatment of animal waste, namely pig manure as a mean of addressing the environmental pollution concerns. In addition, other way in which aerobic composting method has been used for recyling organic mater from pig manure to Biofertilizer plant. Suggestion for possible future application are also presented.

Viet Nam is an agricultural country and animal production makes up about 30 percent of the total value of agricultural production. The animal waste is inevitable consequence of the livestock farming system. With the huge investment in animal production recently, livestock farming systems also have generated considerable amount of manure and mortalities that need to be disposed safely.

In Viet Nam, two main anaerobic methods used for management of manure are biogas and biological lagoon.. Although they are applying extensively, these methods still have some drawbacks. For a general anaerobic method, it usually does not generate necessary heat level (under 600C) to destroy pathogenic agents present in animal manure and will breakdown and pose nutrient loss (especially nitrogen). Using biogas requires high cost to construct system and it is more compatible to large-scale farms. Biological lagoon method can manage only limited amount of manure and this method faces to odour emission. Moreover, this method has been thought to disseminate pathogens into soil, air, and water. For these reasons, it is essential to set up a new method to effectively dispose animal manure.

Aerobic composting method is an optimal technique. It involves the natural biological breakdown of manure into a more stable substance like humus and has some significant benefits. Firstly, aerobic composting method yields necessary heat energy to destroy pathogens and parasites (at peak 740C) and prevents nutrient loss (nitrogen) by creating a biological cover. The composting product is considered as a good type of fertilizer for plants. Secondly, it reduces odour emission to the air. Thirdly, techniques and materials for doing aerobic composting are easy to access. Finally, cost of composting operation and labour expense are low due to the simplicity and shortness of whole process.

The pig manure, rice husk and sawdust were collected from a pig farm in Dong Anh and Gia Lam district, Hanoi city. The manure was analyzed for moisture, carbon and nitrogen content from which a C:N ratio was calculated (Table 1).

|

Table1: Evaluating chemical properties of materials |

||||

|

Properties |

Unit |

Pig Manure |

Rice Husk |

Sawdust |

|

Moisture |

% |

75.5 |

26.3 |

38.6 |

|

Total Nitrogen (N) |

% DW |

3.82 |

0.12 |

0.09 |

|

Carbon (C) |

% DW |

49.5 |

60.3 |

75.7 |

|

C/N ratio |

13 |

500 |

842 |

|

|

P2O5 |

g/kg DW |

5.26 |

2.13 |

4.12 |

|

pH |

6.14 |

|||

The design layout for each of the research trials was a

randomised block design with 4 treatments being tested. Each treatment had 4 replications:

RHmany: Composting of manure and rice husk designed by many layers

RH2: Composting of manure and rice husk designed by two layers

SDmany: Composting of manure and sawdust designed by many layers

SD2: Composting of manure and sawdust designed by two layers

Each compost pile was designed with a base of 1 metre and a total height of 1 metre (Photo 1). Space between piles was approximately 5 metres.

|

|

|

Photo 1: Compost pile |

Recording temperature at 3 locations: outside and inside of piles, air temperature.

Temperature was taken 3 times each position.

For first 24 hours the temperature was taken at 6 hourly intervals, again at 3 locations

Day 2 onwards temperature was taken at 12 hour intervals at the 3 locations.

100 g compost product was taken from core of the pile

One sample from each pile per day for 6 weeks

One sample from each pile taken weekly and submitted for analysis

Concentration of NH3 and H2S was analyzed by Kitagawa detector tubes and gas sensor (MultilLog 2000)

Determination of dry matter

Determination of nitrogen (Kjeldahl method) (N)

Determination of total carbon (C)

Determination of potassium (K)

Determination of phosphorus pentoxide (P2O5)

Determination of pH

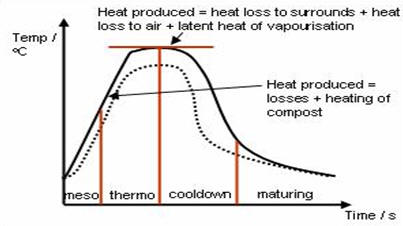

Temperature went through three classic phases: heating phase, thermophilic phase, and cooling phase (Figure 1). During the heating phase, the psychrophilic and mesophilic microorganisms in the piles tended to increase the temperature. As a result of biodegradation of organic compounds, the temperature increased and reached 400C50 0C. During the thermophilic phase, the temperature exceeded the tolerance limit of the mesophilic microorganisms and promoted the development of the thermogenic microorganisms. In this study, the thermophilic phase (>500C) proceeded 4 days.

High temperature of the trials piles reached to a peak at the value of 700C. The results of this research are different with other papers that report on composting . Those papers showed that a maximum temperature increase is to be expected at about day 4 of the process. The explanation for this could be that composting works best where the moisture content of materials in the pile is about 50%-60%. Too much moisture creates soggy mass, and decomposition of organic materials will then be slow as well as the C : N ratio ranging from 20:140:1, especially 30:1, the organic matter decomposes very swiftly.

The line chart reveals that there was a slight fluctuation in temperature of RHmany, ranging from approximately 700C in the second day to nearly 600C in the fifth day then it dropped steeply to the lowest point at roughly 400C in the eighth day. In the eighth day, the composting piles were turn in order to supply oxygen and water. It could be the reasons why temperature recovered sharply to the second peak of upper 600C. Temperature remained nearly 600C during two day then continue its downward trend to approximately 400C in the fourteenth day. The second turning day was the fourteenth day, after that, temperature pick up again, it went up dramatically to the third peak just upper 600C. However, temperature decreased gradually to around 300C in thirtieth day.

Similar to RHmany, temperature in RH2 reached a peak of approximatly 740C in the second day. It stayed at high temperature, ranging from 620C-700C in 4 days. But later, temperature fell remakably to the lowest point of nearly 400C in the fourteenth day. In comparison with RHmany, RH2 remained high for more long time than RHmany. In term of RH2, it was only turned one time compared to two times in RHmany.

Regarding SDmany and SD2, both of them need not turn during 30 composting days. It was also seen that compared with RH treatments, SD treatments remained high temperature for more long time, arough 12 days, ranging from 550C to 700C, between fifth day to seventeenth day.

|

|

|

Figure. 1. Temperature in compost pile |

|

|

|

Photo 2: Peak of compost temperature |

The line chart (Figure 2) provides an glimpse of a variation of moisture in 4 treatments. In comparison with temperature chart, as can be seen that overall, the process of moisture changes is similar the temperature changes. It could be because there was a tight correlation between temperature and moisture. To be more specific, moisture will be reduced by high temperature in composting process. Meanwhile, both high moisture and low moisture will cause low temperature in composting process.

A further outstanding feature in the line chart is that moisture of SD treatments were consistently above moisture of RH treatments, excepting moisture in the turning day of RH treatments. It is due to the fact that sawdust is a compact cover that limitted evaporation of moisture better than rice husk.

This study also found that moisture levels between 46% to 60% are required for the composting process to develop rapidly. If compost material is too dry, decomposition is either very slow or does not occur. Whereas on the other hand, If moisture is too high, aerobic condition in the composting pile become anaerobic condition. Consequencely, aerobic microoganisim cant be active and the composting proccess will be stopped.

This composting process is based on aerobic bacterial activity and bacterial enzyme to biological breakdown the organic nitrogen and carbon sources from pig manure. This process required enough water and oxygen to produce sufficient heat to digest the manure. Biological activity of aerobic bacteria increases are required more water, so using more moisture, therefore moisture level in the trial piles decreased during the experiment time. Shredded wood (sawdust, wood shavings), rice husks may play important role in prevention evaporation of moisture and release odours from the compost piles.

Turning days was conducted at day 8 in the RHmany, fourteenthe day in both RHmany and RH2 by digging into the pile and turning all the material over and adding water to achieve the same moisture levels as during construction. Moisture contents of the compost piles were increased to achieve at around 50%-60%/ At the end of the compost process, moisture levels of compost piles went down to nearly 30%.

|

|

|

Figure 2. Moisture in compost pile |

|

|

|

Photo 3: Measuring gas emissions |

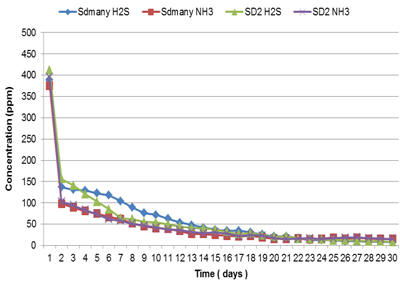

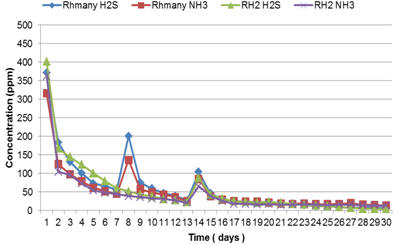

The two line charts (Figure 4) show that concentration of NH3 and H2S fell rapidly from nearly 400ppm in the first day to just upper 100ppm in the second day of composting process. It could be explained by adding wood shaving, sawdust or rice husk (wood shaving, sawdust and rice husk are high in C and low in N) could prevent emission of ammonia odour from the piles. It is also noted that ammonia with enough water is source of nitrogen for bacteria activity. In this trial, sawdust and rice husk have been used as a biofilter. The biofilter play a role as deodorise the gases during the composting process.

With respect to RH treatment, concentration of NH3 and H2S continued downward trend, dropped gradually to around 50ppm in the seventh day. However, it rose significantly in the eighth day in RHmany and in the fourteenth day in botth RHmany and RH2. The explaination for this could be that these days is turning days. Thereforce, opening pile caused NH3 and H2S was released. The end of process concentration of NH3 and H2S went down to approximately 10ppm and 5ppm, respectively.

Similar to RH treatments, there were swift decreases in the concentration of NH3 and H2S of SD treatments in the second day. However, differing from RH treatment, there were not turning days in SD treatments. Thus concentration of NH3 and H2S did not recover like RH treatments. In fact, it fell gradually to roughly 12ppm and 6ppm, respectively.

|

|

| Figure 3. Concentration of NH2 and H2S in compost pile of RHmany and RH2 | Figure 4. Concentration of NH2 and H2S in compost pile of SDmany and SD |

In comparison with the first day, aerobic plate count in the seventhday went down considerably and the highest decrease was SD2 (Table 2). Then it continued dropping substantially in the fourteenth day. But late, in the thirtieth day, aerobic plate count went up significantly compared to the senven day. That could be explained that temperature increased rapidly and maintained high temperature, ranging from 600C to 700C, in the first seven day. The high temperature is one of important factor that killed a major of mesophilic. So that only thermophilic could survive in this period. SD2 remained high temperature for the longest period. Consequencesly, a decrease in SD2 was the highest.

A further striking feature in the table is that after seven composting day, Coliforms, E.coli, Salmonella were not dectected. It could be because they were killed by high temperature that is above maximum temperature they can survive. At the end of this trial it was visible to naked eye by the growth of white fungi on the composting organic materials as well as those materials changed colour to dark.

|

Table2: Evaluating microbial properties |

|||||

|

Time (days) |

Treatment |

Aerobic Plate Count (APC) (109 CFU/g) |

Coliform (106 CFU/g) |

E. coli (106CFU/g) |

Salmonella (106CFU/g) |

|

The first day |

Raw Manure |

48.65 ±0.78 |

101.45±0.26 |

3,23±3.28 |

+ |

|

The seventh day |

RHmany |

3.89 ± 0.49 |

- |

- |

- |

|

RH2 |

3.45 ± 0.26 |

- |

- |

- |

|

|

SDmany |

2.87 ± 0.19 |

- |

- |

- |

|

|

SD2 |

2.13 ± 0.52 |

- |

- |

- |

|

|

The fourteenth day |

RHmany |

2.24 ± 0.35 |

- |

- |

- |

|

RH2 |

2.09 ± 0.37 |

- |

- |

- |

|

|

SDmany |

1.79 ± 0.33 |

- |

- |

- |

|

|

SD2 |

1.47 ± 0.16 |

- |

- |

- |

|

|

The thirtieth day |

RHmany |

3.12 ± 0.71 |

- |

- |

- |

|

RH2 |

3.35 ± 0.26 |

- |

- |

- |

|

|

SDmany |

2.83 ± 0.29 |

- |

- |

- |

|

|

SD2 |

3.16 ± 0.72 |

- |

- |

- |

|

|

|

Figure 5. Temperature phases in compost process |

Chemical properties of final composting product

It is a well- documented fact that nitrogen is one of important nutrient for plant. In comparison with table 1, it is can be seen that the total nitrogen decreased after 30 days of composting process (Table 3). However, the major of total nitrogen was kept in the final composting product with nearly 2%DW. Sawdust and rice husk constituted biocover that limited nitrogen loss, especially NH3. Thereforce, final composting product can be used as a nutrient and safe biofertilizer.

|

Table 3: Chemical properties of final composting product |

|||||

|

Properties |

Unit |

Final Composting Product |

|||

|

RHmany |

RH2 |

SDmany |

SD2 |

||

|

Moisture |

% |

29.0 |

32.3 |

34.4 |

32.0 |

|

Total Nitrogen |

% DW |

1.81 |

1.67 |

1.93 |

2.04 |

|

Total Cabon ( C ) |

% DW |

22.3 |

23.1 |

42.7 |

40.7 |

|

C/N |

|

11 |

14 |

22 |

20 |

|

P2O5 |

g/kg DW |

4.47 |

5.02 |

5.16 |

4.94 |

|

pH |

|

6.69 |

6.93 |

6.82 |

6.73 |

|

|

|

Photo 4: Compost Fertilizer |

Conclusions

The temperatures in the composting piles reached above 600C to 700C after 24h - 48h during the trials process were detected in this study. High temperatures favour the micro-organisms that are the most rapid decomposition of the organic materials as pig manures. At the end of the trials process, the temperature in the 4 treatment went down to nearly 300C, little heat was produced.

Moisture levels between 46% and 60% are required for the composting process to develop rapidly. Water content of the composting piles went down during the composting process that lead to decrease temperature in the composting piles.

Aerobic composting method can limit odour emission significantly.

This small-scale rapid compost could be apply for treatment animal waste because of these reason: (1) It easily implement at the small-scale farms, no require more lands, labours, (2) Organic materials using in composting process are very common in rural area such as rice husk, straw, wood shaving, sawdust, (3) Good for public health: Treatment the zoonoses pathogens as viruses, bacteria, parasites, (4) Preventing environment pollution: No contamination of water sources, no odour release, (5) Economical matters: products of compost as Biofertilize for cultivation of agronomy.

The authors are grateful to the MEKARN project, financed by the Sida-SAREC agency. Thanks are also due to 8 farms in Dong Anh and Gia Lam District, Hanoi City, who participated actively in this study.

References

Abdelhamid, M.T., Horiuchi, T. & Oba, S 2004 Composting of rice straw with oilseed rape cake and poultry manure and its effects on faba bean (Vicia faba L.) growth and soil properties. Bioresource Te c h n o l o g y, 13 , 183189.

Bernal, M.P., Lopez-Real, J.M., Scott, K.M 1993 Application of natural zeolites for the reduction of ammonia emissions during the composting of organic wastes in a composting simulator. Bioresour. Technol. 43, 3539.

Bernal, M.P., Navarro, A.F., Roig, A., Cegarra, J., Garcνa, D 1996 Carbon and nitrogen transformation during composting of sweet sorghum bagasse. Biol. Fert. Soils 22, 141148.

Bhamidimarri, S.M.R. & Randey, S.P 1996 Aerobic thermophilic com-posting of piggery solid wastes. Water Science and Technology, 33, 8994.

Brewer, L.J. & Sullivan, D.M 2003 Maturity and stability evaluation of composted yard trimmings. Compost Science and Utilization, 11, 96112.

Charest, M.H. & Beauchamp, C.J 2002 Composting of de-inking paper sludge with poultry manure at three nitrogen levels using mechanical turning: behavior of physico-chemical parameters. Bioresource Technology, 81 , 717.

Chnitzer, M., Dinel, H., Mathur, S.P., Schulten, H.R. & Owen, G 1993 Determination of compost biomaturity-III. Evaluation of a colori-metric test by 13C NMR spectroscopy and pyrolysis-field ionization mass spectrometry. Biology of Agricriculture and Horticulture, 10, 109123.

Cunha-Queda, A.C., Ribeiro, H.M., Ramos, A. & Cabral, F 2007 Study of biochemical and microbiological parameters during composting of pine and eucalyptus bark. Bioresource Technology, 98, 32133220.

DeLaune, P.B., Moore, P.A., Daniel, T.C. & Lemunyon, J.L 2004 Effect of chemical and microbial amendments on ammonia volatil-ization from composting poultry litter. Journal of Environmental Quality, 33 , 728734.

EN 13039 1999 Soil Improvers and Growing Media Determination of Organic Matter Content and Ash. European Committee for Stand-ardization, Technical Committee CEN/TC 223.

Fauci, M.F., D.F. Bezdicek, D. Caldwell, and R. Finch 1999 End product quality and agronomic performance of compost. Compost Sci. Util. 7, 1729.

Felton, G.K., L.E. Carr, C.E. Prigge, and J.C. Bouwkamp. 2004. Nitrogen and phosphorus dynamics in cocomposted yard trimmings and broiler litter. Compost Sci. Util. 12, 349355.

Hao, X., C. Chang, and F.J. Larney 2004 Carbon, nitrogen balances, and greenhouse gas emission during cattle feedlot manure composting. J. Environ. Qual. 33, 3744.

Hickman, G., and N. Hughes 2002.Carcass disposal: A major problem of the 2001 FMD outbreak. State Vet. J. 12:2732.

Paredes, C., Bernal M.P., Cegarra, J. & Roig, A 2002 Bio-degradation of olive mill wastewater sludge by its co-composting with agricul-tural wastes. Bioresource Technology, 85 , 18.

Pereira Neto, J.T 1987 A Low Cost Technology Approach on the Treat-ment of Municipal Refuse aAnd Sewage Sludge using Aerated Static Pile Composting. PhD Thesis, Department of Civil Engineer-ing, University of Leeds, England.

Petersen, S.O., Lind, A.-M., Sommer, S.G 1998 Nitrogen and organic matter losses during storage of cattle and pig manure. J. Agric. Sci. Cambr. 130, 69 79.

Poulsen, H.D., Kristensen, V.F 1998 Standard Values for Farm Manure. DIAS Report No. 7. Beretning no. 736. Tjele, Denmark.

Roletto, E.R., Barberis, M., Consiglio, M. & Jodice R 1985 Chemical parameters for evaluation compost maturity. Biocycle, 26 , 4647.

Sung, S. & Santha, H. 2001 Performance of temperature-phased anaerobic digestion (TPAD) system treating dairy cattle wastes. Tamkang Journal of Science and Engineering, 4, 301310.

Ten-Hong, C. & Wu-Huann, S 1996 Performance of four types of anaerobic reactors in treating very dilute dairy wastewater. Bio-mass and Bioenergy, 11, 431440.

Tiquia, S.M 2005 Microbiological parameters as indicators of com-post maturity. Journal of Applied Microbiology, 99, 816828.

Tiquia, S. M. & Tam, N.F.Y 2002 Characterization and composting of poultry litter in forced-aeration piles. Process Biochemistry, 37, 869880.

Wafula, M.M., Patrick, A., Charles, T 2008 Managing the 2004/05 anthrax outbreak in Queen Elizabeth and Lake Mburo National Parks. Uganda. Afr. J. Ecol. 46, 2431.

Ward, A.J., Hobbs, P.J., Holliman, P.J., Jones, D.L 2008 Optimisation of the anaerobic digestion of agricultural resources. Bioresource Technol. 99, 79287940.

Wilkinson, K.G 2007 The biosecurity of on-farm mortality composting. J. Appl. Microbiol. 102, 609618.

Zhu, J., Jacobson, L., Schmidt, D., Nicolai, R

2000 Daily variations in odor and gas

emissions from animal facilities.Applied Engineering in Agriculture 16 (2),

153158.