Low-cost biodigesters as the epicenter of

ecological farming systems

T R Preston and Lylian Rodríguez

University

of Tropical Foundation ,

Cambodia

Abstract

Much of the developmental work

with biodigesters has been approached from the engineering viewpoint with

emphasis on design and construction with the aim of maximizing gas production

and efficiency of conversion of feedstock to biogas. There has been very little change in the

basic designs of the floating canopy (as developed in

The introduction of the

low-cost (< USD 50.00 for a family size unit) plastic biodigester, based on

the use of tubular polythene film, put the technology within reach of a greater

number of end users (more than 20,000 users in

Future needs are: to document the observed improvement in

fertilizer value of the biodigester effluent compared with the raw manure; to

understand the factors influencing this process; and to improve the design of

the low-cost plastic biodigester so as to increase efficiency and rates of gas

production.

Key words:

Biodigesters, farming system, effluent, fertilizer, design and

construction

Introduction

Biodigesters have been considered primarily as a means of

producing a combustible gas from waste organic matter, derived from animals or

people. In this respect, the

developers of this technology have been mainly concerned with details of the

design and construction of biodigesters, and of management strategies, which

would lead to maximum rates of gas production. Less attention was given to the other

output from the biodigester, namely the effluent resulting from the digestion

process.

As a result of the increasing emphasis on the promotion of

farming systems based on the sustainable use of natural resources, it is now

appreciated that the biodigester should be considered in a much wider

perspective and specifically in its potential role for the recycling of plant

nutrients. This process has

implications both as a means of reducing the dependence on inorganic fertilizers

and for facilitating the production of foods and feeds of organic origin.

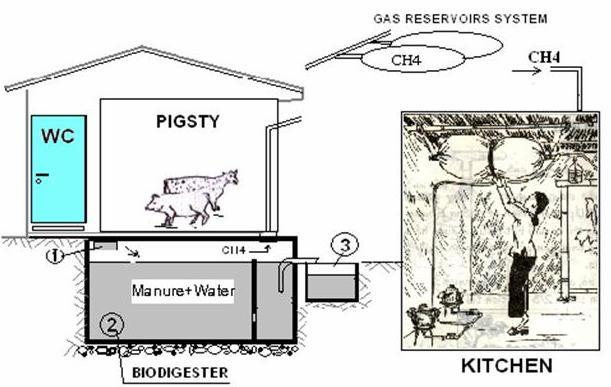

The biodigester in the farming system

For farming systems to be sustainable there should be a close

relationship among the different components that interact in the conversion of

solar energy and soil nutrients into food of animal and plant origin for the

benefit of both the consumer and the producer (Figure 1).

Figure 1:

The integrated farming

system

Seen in this context the biodigester plays several roles. It can be:

- A source of fuel for

cooking

- A source of fertilizer

for:

- Crops

- Water plants

- Fish ponds

- Crops

- A means of de-contaminating wastes rich in

organic matter

The appropriate use of biodigesters can also give rise to a

number of related socio-economic benefits that come about through improvements

to:

- The quality of life for rural women and

children due to:

- Reduced workload (less firewood has to be

collected!!)

- Cleaner kitchen and cooking

utensils

- Reduced workload (less firewood has to be

collected!!)

- The fertilizer value of manure

- Organic N is converted to

NH4-N

- Organic N is converted to

NH4-N

- The environment

- Reduced methane

emissions

- Less deforestation

- Reduced methane

emissions

Research on the biodigestion process should therefore proceed along a number of pathways, namely:

- Design and construction, with the aim of reducing installation costs and / or improving the efficiency of converting the input materials into usable end-products

- Changes that take place in the biological and chemical characteristics of the substrate during the process of biodigestion

- Use of the effluent as fertilizer for soil and water plants and for fish ponds

Design and construction of the biodigester

Much of the developmental work with biodigesters has been

approached from the engineering viewpoint with emphasis on design and

construction with the aim of maximizing gas production and efficiency of

conversion of feedstock to biogas.

There has been very little change in the basic designs of the floating

canopy (as developed in

The introduction of the low-cost (< USD 50.00 for a family

size unit) plastic biodigester, based on the use of tubular polyethylene film

(Botero and Preston1985; Bui Xuan An et al 1997a,b), put the technology within

reach of a greater number of end users. It has been estimated that there are

more than 15,000 users of this technology in

The Hybrid Technology Biodigester with

Automatic Scum Control (HTASC)

This modification of the low-cost plastic biodigester system (VACVINA 1998) was directed at improving

the durability of the digestion chamber by constructing it from bricks and

cement. The HTASC is a cross between an underground

fixed dome (Chinese) model and a plastic-bag model. The main digestion chamber

is a rectangular (flat-topped) low-depth underground cement tank. There is no

pre-digestion / mixing chamber, but instead a siphon-type input with active and

continuous scum-breaking action. The effluent is gravity fed to a secondary

chamber. This design facilitates the integration of the livestock pen and

household latrine with the biodigester, thus saving space and reducing the

overall costs of construction (Figure 2).

Positive results with this digester design have been reported

from Vietnam (VACVINA 1998), however, it has been less successful in a pilot

test in Cambodia, due apparently to gas leakage through the walls and /or roof

of the digestion chamber, which was only resolved by connecting the input

siphons to the traditional polyethylene model (http://www.utafoundation.org/recdevel.htm

and Preston T R 2001, unpublished

observations). The idea is an

interesting one which merits further research and, specifically, the development

of appropriate techniques to ensure the concrete surfaces are gas-tight.

The “Super-gas” mixing system

The objective behind the development of this model is to increase the rate and efficiency of the gas production from the substrate by using the gas pressure generated in the reactor to trigger the movement of the substrate between the reactor and the reservoir chambers. The digester is made from PVC sheets welded into a “balloon”. Two balloons are inter-connected to permit free movement of the substrate from one to the other and a simple “water” valve controls the build-up and release of the gas pressure (Figure 3).

Figure 3:

The “super-gas” mixing biodigester

installed in UTA,

The biodigestion process

The changes that take place in the substrate during the

digestion process have received less attention and have been concerned mainly

with environmental and health issues.

Thus the degree of reduction in the Biological Oxygen Demand (BOD) and in

the concentration of pathogenic micro-organisms have been major areas of

interest (Chara et al 1999; Vieyra 2000;

Pedraza et al 2002).

Recently, attention has focused more on the fertilizer value

of the effluent and specifically on comparisons of the effluent with the raw

manure used to charge the digesters. Thus Le Ha Chau (1998a) showed that the

biomass yield and the protein content of

cassava foliage were significantly increased when biodigester effluent,

derived from either pig or cow manure, was used to fertilize the cassava as

compared with the same amount of nitrogen applied in the form of the raw manure

used to charge the biodigester.

Similar findings were reported for duckweed grown in ponds fertilized

with the effluent or the raw manure (Le Ha Chau 1998b). Kean Sophea and

Reports from

Conclusions

The increasing emphasis on the need to develop agricultural

practices that are in harmony with the environment, and which make maximum use

of local resources, is creating a

favourable climate for promotion of biodigester technology. Future research in this area

should focus on the role of the biodigester as an integral component of the

farming system, with major emphasis on ways to optimize the fertilizer value of

the effluent and its use on crops and in ponds for water plants and fish. There

is opportunity for improvement in the design and management of low-cost plastic

biodigesters in order to make them more productive and efficient.

References

Botero R

and Preston T R 1987

Biodigestor de bajo

costo para la produccion de combustible y fertilizante a partir de excretas.

Manuscrito ineditado: CIPAV, Cali, Colombia

Bui Xuan An,

Bui Xuan An, Rodríguez L, Sarwatt S

V, Preston T R and Dolberg F 1997b Installation and performance of low-cost

polyethylene tube biodigesters on small-scale farms. World Animal

Review Number 88 FAO Rome http://www.fao.org/ag/AGA/agap/frg/feedback/war/W5256t/W5256t06.htm#TopOfPage

Chara J,

Pedraza G X and Conde Natalia 1999 The productive

water decontamination system: A tool for protecting water resources in the

tropics. Livestock Research for Rural Development (11) 1: http:/www.cipav.org.co/lrrd/lrrd11/1/cha111.htm

Ding Jieyi and Han Yujin 1984

Comparative studies on the effects of

fresh pig manure and anaerobically fermented pig

manure upon fish farming, Proceedings Integrated Fish

Farming Systems. Fresh Water Fisheries Research Centre of

Kean Sophea and

Le Ha Chau

1998a Biodigester effluent versus manure from pigs or cattle as

fertilizer for production of cassava foliage (Manihot

esculenta). Livestock Research for Rural Development (10)

3: http://cipav.org.co/lrrd/lrrd10/3/chau1.htm

Le Ha Chau 1998b

Biodigester effluent versus manure, from pigs or

cattle, as fertilizer for duckweed (Lemna spp.). Livestock Research for Rural Development (10)

3: http://cipav.org.co/lrrd/lrrd10/3/chau2.htm

Pich Sophin and

VACVINA 1998 Hybrid Technology Biodigester with

Automatic Scum Control (HTASC). Center for Rural Communities.

Vieyra R R 2000 Monitoreo de biodigestor de bajo costo usando