Transferring the low cost plastic film biodigester technology to farmers

Duong Nguyen Khang and Le Minh Tuan*

Department of Animal Physiology and Chemistry, University

of Agriculture

Thu Duc district, Ho Chi Minh City , Viet Nam

khang@hcm.vnn.vn

*Biogas centre, University

of Agriculture and Forestry,

Thu Duc district, Ho Chi Minh

City, Viet Nam

Abstract

The

Key words: Low cost plastic film biodigester, technology transfer, development, socio-economic impact

Research and Development

The first plastic film biodigester in Viet Nam was

established in 1992 at the University of Agriculture and Forestry, Thu Duc district, Ho Chi Minh City.

The initiative was part of a project funded by SidaSAREC

and FAO on strategies to promote sustainable use of local resources in

livestock-based farming systems (

|

Table 1:

Biogas production of plastic film biodigester |

|

|

Biogas production (litres/kgOM/day) |

References

|

|

226 |

Pham

Van Minh 1995 |

|

229 |

Phan

Duc Quy 1997 |

|

244 |

Nguyen Thanh Quoc 2000 |

|

214 |

Nguyen Viet Lap 2001 |

The biogas yield

of the plastic film biodigester reported in four sites (Table 1) was lower than

that from a fixed dome concrete biodigester which was 340 litres/kg

of OM according to Nguyen Van Thuan (1984). However,

the biogas was enough for cooking at the householder level. The reason of the lower biogas

yield in the plastic film biodigesters was possibly because the ratio of

man ure to water was too low.

|

Table 2: Effect of the biodigestion process on COD level and faecal pathogens |

|||

|

Parameters |

Manure |

Effluent |

References |

|

COD (mg/litre) |

4021 |

1646 |

Pham Van Minh (1995) |

|

2451 |

789 |

Phan Duc Quy (1997) |

|

|

1079 |

441 |

Nguyen Thanh Quoc (2000) |

|

|

633 |

170 |

Nguyen Viet Lap (2001) |

|

|

E.coli (MNP/ml) |

52.9 x 106 |

75.4 x 103 |

Pham Van Minh (1995) |

|

6.8 x 105 |

7.3 x 104 |

Nguyen Thanh Quoc (2000) |

|

|

28.3 x 105 |

1.9 x 105 |

Nguyen Viet Lap (2001) |

|

|

Coliform (MNP/ml) |

266 x 106 |

236 x 103 |

Pham Van Minh (1995) |

|

46.3 x 106 |

26.9 x 105 |

Nguyen Thanh Quoc (2000) |

|

|

87.8 x 105 |

43 x 105 |

Nguyen Viet Lap (2001) |

|

The COD (chemical oxygen de

Transfer of the technology

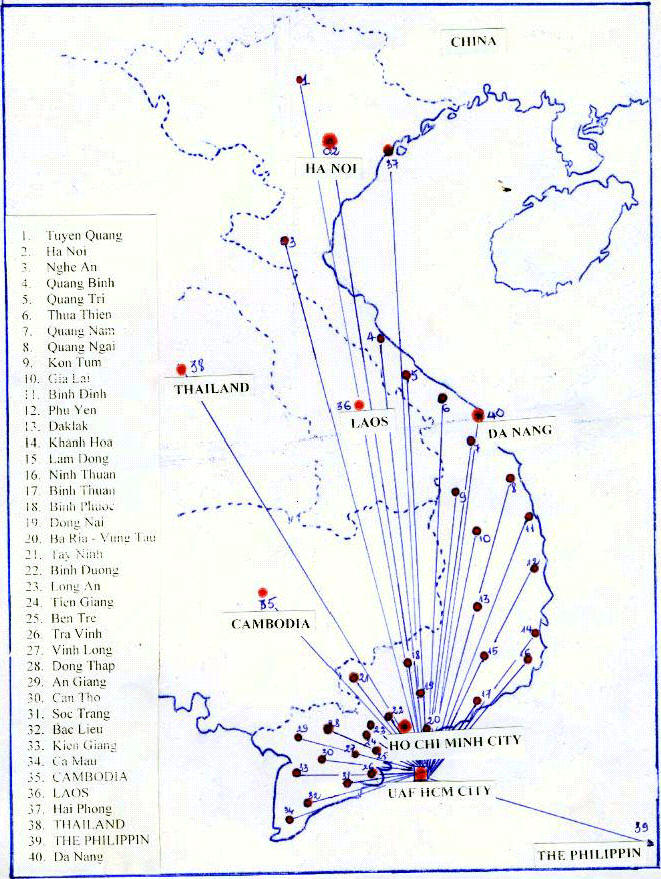

More than 40 provinces in

|

|

|

Photo 1: Transfer of the plastic film biodigester technology |

More than 15,000 units have been set up in Vietnam during the past ten years, with numbers

installed annually showing a consistent increase (Figure 1). There have been marked

differences among regions. The numbers installed in the South-eastern part of

Figure 1: The numbers of

biodigesters installed annually since 1992 (data for 2001 are not complete)

Figure 2:

Numbers of biodigesters set up in

the

Figure 3: Lifetime of plastic film biodigesters

A survey was made of 200 households having installed plastic film biodigesters since 1995 (Figure 3). Most of the units were still working up to five years after installation and some even longer, where there had been good protection.

Economic and environmental impact of the plastic biodigester technology

The cost of a

10m³ capacity biodigester (operating and capital costs) was estimated to be USD100.00.

This is equivalent to a cost of USD6.00/month for the gas used for cooking.

Therefore, with an interest rate of 6%, the payback period of the biogas system

would be 1.5 years. This does not take

into account the positive effect of the technology on environmental parameters.

The global advantages of the low-cost plastic biodigester technology

Economic advantages

-

Produces cheap gas for poor farmers to replace industrial gas and wood.

-

Creates new jobs, especially in the energy sector, and thereby decreases the unemployment rate in the country and stimulates the rural economy.

-

Reducing work load for women to look for fuel in the field.

-

It burns with a clean bluish flame thereby making it non-messy to cooking utensils and kitchens.

-

The effluent is an excellent fertilizer for soil and water crops and fish ponds

Environmental advantages

-

Biogas does not contain toxic carbon monoxide so no danger to health and no offensive odour.

-

Reduction in pollution as BOD and COD and fecal pathogens are considerably reduced.

Advantages and disadvantages of using plastic film biodigesters from the point of view of individual householders

Advantages:

-

The plastic film biodigester is simple and easy to construct from readily available materials and its operation does not require special skills.

-

Farmers can do the set up by themselves.

-

Biodigester technology enhances energy supply decentralization, for instance rural communities having difficulties or no access to commercial fuels can produce biogas to meet their fuel needs, thereby increasing reliability of fuel supply and enhancing energy security to the rural areas.

-

Plastic film biodigesters can be used for treating the waste water in live stock units

-

Reducing the work of women in the household.

Disadvantages:

-

The initial investment cost may be too high for poor families in rural areas.

-

Plastic film biodigester could therefore be acquired only by the relatively richer farmers.

-

Plastic film biodigesters are easily damaged physically and by sunlight

-

Requires a considerable amount of residential space.

-

Not enough high pressure for the flame (about 2 cm water column)

-

Decrease of biogas production with drop in air temperature and in salt water areas.

Recommendations and policy implications:

Relatively high investment capital and maintenance cost is a

major impediment to the adoption of plastic film biodigesters in the rural

areas for poor farmers. Considering the long-term benefit of plastic film

biodigester technology both economically and environmentally, it may be

necessary to introduce some financial incentives to promote its penetration and

diffusion into rural areas. The government agencies such as Department of

Environment, Department of Agriculture and Rural Development,

Research, development and demonstration are essential activities to overcome the technical obstacles and be well abreast of development in biogas technology. Government support will also be needed. Major research areas will include:

-

Development and use of local materials for the construction of biogas plant,

-

Improved fermentation process to obtain high biogas generation,

-

Design specification for different plant sizes (plant construction techniques, effluent distribution, operation problems, gas appliances…),

-

Development of effective and cheap appliances,

-

Socio–cultural factors that affect the adoption of biogas technology,

-

Evaluation of the technology.

-

Intensification of networking activities in rural areas for poor farmers to understand how to protect the environment for development of suitable agriculture.

References

Nguyen Viet Lap 2001. Effects of loading rate and

retention time on the rate of biogas production in plug-flow and liquid

displacement biodigesters. Thesis. University of Agriculture and

Forestry, Thu Duc, HCM city.

Pham Van Minh 1995 A survey on the technological developments of plastic film biodigester in East areas of the South of Viet Nam. Thesis. University of Agriculture and Forestry, Thu Duc, HCM city

Preston T R 1990 Livestock Production from Local Resources in an Integrated Farming System; a Sustainable Alternative for the Benefit of Small Scale Farmers and the Environment. Proceedings National Workshop-Seminar on Sustainable Livestock Production on Local Feed Resources. Ho Chi Minh City, Vietnam, January 18-20th 2000.

Nguyen Thanh Quoc 2000 Effect

of loading rate of pig

Phan Duc Quy 1997 A survey on the usage and development of plastic film

biodigester in East areas of the South of Viet Nam. Thesis.

Nguyen Van Thuan

1984 Guidance on the biogas production and usage. Journal of Dong Nai province.

Environmental Regulations of