· Biogas Energy Department.

· Wind and Solar Energy Department.

· Rural Energy Planning and Fuel Department.

·

Hydro-Power Department.

Research activities of Energy Institute in the field of Biogas Technology

· Design, construction, fabrication and test experiment of biogas plants and appliances

· Implement development projects in the whole country.

· Provide technical services for users.

· Provide training services for technicians and masons and transfer technology to other organizations.

·

Prepare technical

The main results of the development activities are as follows:

Number of plants installed in localities:

· Floating-gasholder made of steel sheet: 97

· Floating-gasholder made of ferro-cement: 50

· Fixed-dome built of brick: 186

Number of video tapes: 5, of which 4 video films have been diffused on Vietnam

Number of man

In collaboration with "Institut de I'Energie des pays ayant en commun

I'usage du francais (IEPF)" on preparation of the

man ual

"La filiÌre biogaz dans les pays en developpement".

Number of training courses: 7

Implementation of 3 projects supported by OXFAM, UNICEF and ACCT (Agence de cooperation culturelle et technique).

Design, construction, and test experiments of biogas plants

To

evolve low-cost designs suitable for

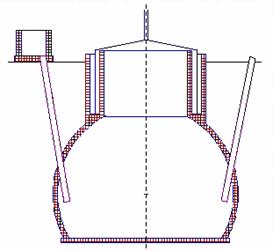

Floating gasholder plant (Figure 1).

This type of plant was mainly developed before 1984 with digester volume of 1 to 50 m3. Disadvantages are the cost of the plant needs to be brought down further, especially by replacing the steel gasholder.

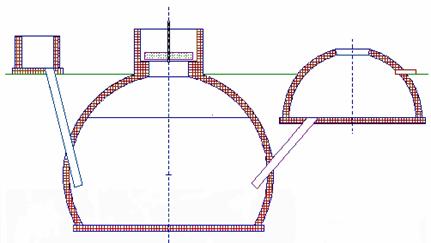

Fixed - dome plant (Figure 2)

Since 1984 IE has concentrated on the design and development of a fixed dome digester with the spherical shaped wall built of brick. The first digester of this type was installed in 1987. More than 200 plants with the digester volume from 1 to 15 m3 have been constructed since 1988. This type was evaluated in 1990 and has replaced the floating gasholder one for popular extension. A computer program was compiled for calculating volumes, dimensions and drawing. The spherical structure is now applied for design of floating gasholder plants.

Figure 1:

Spherical shaped floating gasholder plant

Figure 2: Spherical shaped

fixed - dome plant

Application of biogas

Besides researching biogas for cooking and lighting, we are also interested in researching biogas as a clean fuel for other aspects. For example, biogas can be used for electricity generating, tea processing, fruit storing and hatching chickens. But some are still in process of trial, demonstration or further development. In this paper we only discuss two applications of biogas to generate electricity and for the storing of oranges.

Biogas in electricity generating

To use

biogas as a fuel for the international combustion engine, the engine must be

refitted. We have chosen to modify the smallest capacity of 4-stroke petrol

engine popular in the Vietnamese market named Shriram Honda EM650. It is simple

to refit the petrol engine: add a biogas-air mixer to the original carburettor,

and then biogas can be used to replace petrol to power the engine.

|

Table 1: Properties of

biogas-petrol engine Shriram Honda EM650 with real power of 50VA (Maximum

power of 550VA) |

|||

|

Parameters |

Unit |

Petrol |

Biogas |

|

Capacity |

|

|

|

|

At limited power regulation |

W |

143 - 550 |

220 - 360 |

|

At least fuel consumption level |

W |

400 |

360 |

|

Unit fuel consumption |

|

|

|

|

At limited regulation |

litres/kwh |

1.1 - 2.3 |

1300 - 1700 |

|

At least fuel consumption level |

litres/kwh |

1.1 |

1300 |

|

|

litres/hour |

0.44 |

468 |

The experience shows that to generate

electricity with biogas produces good economical results as 1m3 of

biogas can replace 0.85 litres of petrol. A generator of 450 VA requires 3 m3

of biogas for 5 hours each evening. The biogas plant must have a minimum

digester volume of 10 m3 (30 pigs with weight of about 50 kg/head or

15 cattle). The electricity power is sufficient for 3 electric bulbs of 100W

(or 7 fluorescent lights of 40W) and 2 electric appliances like television or

radio sets of 75W.

Biogas in orange storing

Use

of biogas to store oranges has the advantages of being simple, economical,

effective and without toxicity poisoning. This method has been sucessful in

Conclusion

The

experience gained from the multi-use and social response to biogas technology

reveals it to be appropriate for wide scale application in rural areas in

In

addition, in urban areas, anaerobic technology can be also applied to treat

industrial wastes and waste waters. It not only saves energy but also produces

more energy during wastewater and solid waste treatment processes. The tropical

climate is a very suitable condition for anaerobic fermentation. Consequently,

this technology should be disseminated for meeting the de

· Integration of biogas programs at all levels of policies and planning processes.

· Local, regional and national budgets have to provide allocations mainly for promotion, training, building and improvement of necessary infrastructure, R&D and implementation programs.

· Initially, adequate incentives and regulatory measures in tax-structures and other laws must be provided to bring biogas programs to equal terms with competing technology systems. This will also encourage NGO¢s and private entrepreneurs.