Utilization of Fly larvae, Earthworms and Duckweed

for Frog production in an Integrated Farming System

Latsamy Phounvisouk

LivingAquatic Resources Research

Center (LARReC)

NaongThang Villged, Vientiane City, Laos

PDR

Meetouna@yahoo.com

1. Introduction

Livestock excreta are a major source of environmental pollution

in intensive, specialized animal agriculture (Steinfeld et

al., 2006). According to Kirschenmann (2007)

"Agro-ecologists increasingly are convinced that the most viable

alternative technology will spring from the biological synergies

inherent in multispecies systems and that additionalresearch might

make such systems the next new technology". Integration of crops

and livestock, with recycling of the manure, is considered to be

the basis of new management systems, "with the potential to

increase the quantity and quality of production and the economic

return to the farmers while at the same time placing less degrading

pressure on soil and water resources." (Franzluebbers, 2007). One

way of improving animal production without negative effects on the

environment and increasing the efficiency of resource utilization

is by integrating all the processes in the system, in the context

of the sustainable use of those resources (Sophin and Preston,

2001).

To solve the problem of pollution, and to make better use of

animal excreta, there are several techniques that can be applied.

Biodigesters

Anaerobic biodigestion is one of the most efficient technologies

for converting animal manure into useful products: gas for cooking

and effluent for fertilizer (Preston and Rodriguez 1998). For

small-scale farms the plastic biodigester, because of its low cost

and simple construction and management, may be the preferred

technology (Bui Xuan An et al., 1997). The effluent is a

valuable product from biodigesters and has been shown to be

superior to the original manure for fertilization of crops (Le Ha

Chau 1998) and fish ponds (Pich Sophin and Preston 2001). The

effluents from biodigesters, when suitably diluted, are very

effective media for growing duckweed (Le Ha Chau

1998).

Earthworms

The cultivation of earthworms can be another component of manure

recycling. They have a comparative advantage over other forms of

recycling when the manure is from goats or rabbits (Preston and

Rodriguez 1998).

Fly larvae

Manure is the principal food of many insects in nature, house

fly (Muscadomestica Linnaeus). The larvae convert

residual manure proteins and other nutrients into their biomass,

which is rich in high quality animal protein. Also, while occupying

the manure they aerate and dry it, reducing odors.

Aquatic plants

Aquatic plants are being promoted as important components in

management of livestock wastes, especially in large scale intensive

units (Steinfeld et al., 2006). According to Leng

(1995).farmers throughout Asia have harvested naturally produced

aquatic plants for a number of purposes including animal feed,

green manure and for their family feed resources. "The best known

of these is "duckweed", which has become prominent, because of its

ability to concentrate minerals in heavily polluted water such as

that arising from sewage treatment facilities"(Leng 1995). It has

also high potential as a feed resource for fish (Leng et

al., 1994), ducks (Bui Xuan Men et al., 1997) and pigs

(Du Thnh Hang 1998). Duckweed grows on water with relatively high

levels of N, P and K and concentrates the minerals and synthesises

protein.

Potential of frog cultivation in waste recycling

Live stock play two roles in waste recycling. On the one hand

they maybe the cause of pollution if their manure is discharged

directly to the environment. However, certain species may be able

to benefit directly from products that arise in an efficient system

of waste recycling. Aquatic animals are most suited for the

utilization of products of recycling since their normal habitat is

either wholly or partially in natural or artificial water bodies.

The common lowland frog (Rana rugulosa) appears to

be specially adapted for cultivation in integrated farming systems,

since its natural feed source includes insects and earth worms. In

the Northern region of Laos, there is a high demand for consumption

in family households and local markets. The frog is fast growing.

From hatching to market size, it takes 3 to 4 months which is

similar to other commercial species such as catfish and tilapia.

Frogs can be raised in all locations in Laos, as they require small

area and lower quantity of water than other aquaculture species

(Bounsong, 2001).

2.

Objectives

The aims of the present study were to investigate components in

a waste recycling system which could be used for the cultivation of

frogs, to reduce the present dependency on imported concentrate

feeds, and to make the system more attractive for small-scale

farmers in Laos.

Two experiments have been carried out. The first experiment was

a study of the effect of different sources of household waste,

irrigated with biodigester effluent, on the production of fly

larvae. The second experiment compared the use of fly larvae and

earth worms, with or without duck weed, as the basal diet for

growing frogs raised in ponds.

Table of contents

3.1. Biological characteristics and

feeding behaviour of frog species. 9

3.1.1. The common lowland frog,

(Rana Rugulosa)9

3.1.5. Nutrient Requirements.

10

3.2. Frog production in Aquaculture

systems. 10

3.3. Earthworm as a feed source for

livestock and frog production. 11

3.3.1. Significance of Earthworm in

animal production. 11

3.3.2. Feed and feeding of

Earthworm.. 11

3.3.3. Nutritive value of

earthworms. 11

3.4. Nutritive value of fly

larvae. 12

3.4.1. Larvae as a feed source for

livestock production. 13

3.4.2. Research on fly larvae in the

past13

3.4.3. Production of fly larvae.

13

3.4.4 Fly larvae and chitin.

14

3.5. Biodigesters in integrated

farming systems. 17

3.7. Water quality parameters for

Frogs. 18

4. Conclusions and recommendations.

19

3.

General discussion

3.1. Biological characteristics and feeding

behaviourof frog species

3.1.1. The common lowland frog,

(RanaRugulosa)

The local lowland frog, Rana rugulosa Wiegmann,

locally called "Kob Thong" or "Kob Jarn" is one of 38 frog species

found in Laos. At present, four native and one introduced species,

RanaRugulosa, Rana tigerina, Rana marcrodon, Rana

blythii and Rana catesbeiana (bullfrog),

respectively, are most preferred in both local and foreign markets.

Because of a high demand, frog farms continue to expand throughout

the SE Asia region (Thongyount, 2004).

3.1.2. .Natural

habitat

The lowland frog is generally found in various water bodies and

wet or damp areas. They can be found in a considerable distance

from their aquatic habitat because of their wandering

behavior.

3.1.3. Food and

feeding

The lowland frog (Rana rugulosa)is a carnivorous

amphibian, feeding on earthworms, insects, spiders, worms, small

fish and small frogs (Akasay, 1994). In their natural habitat,

frogs have a variety of foods to select except at times of

unfavorable environment or seasonal conditions. In Thailand, frog

culture is usually conducted in concrete tanks, floating net cages,

or in ponds with commercial feed (Kamonphone, 1977).

3.1.4. Stocking

density

After they are taken from tadpole ponds, young frogs can be

stocked in culture pens or concrete tank at up 30 frogs per square

meter (Grey Lutz and Jimmy, 1999).

3.1.5. Nutrient

Requirements

The lowland frog require similar nutrients as other aquatic

animal species, especially those that are carnivorous, to maintain

normal growth and metabolic function. The major nutrients such as

protein, lipids, essential fatty acids, carbohydrates, vitamins and

minerals are required for normal growth (LARReC,

2001).

The dietary protein requirements for frogs have been determined

in various studies. According to Thongyount (2004), protein levels

start at 38% in DM for tadpoles (1-30 days), reducing to 32% for

small frogs (30-60 days) and 26% for fattening frog (60-90 days).

Artificial feed of 35 % crude protein supported faster growth in

Rana pipen tadpoles than young tilapia fish of 23 %

protein (Ling et al., 2003). Feeding of ensiled fish, over a

period of 4 months, enabled frogs to reach a live weight of 200 to

400g (Marttinez, 1993). According to Martinez et al., (1993)

commercial feeds with 39% protein feed are suitable for frogs in

intensive culture.

3.2. Frog production in Aquaculture

systems

In general, there are three forms of frog culture: in ponds,

cages and tanks. Each system has its own important characteristics

and the decision as to which system to use will depend on the

purpose of the operation. Cage and tank culture are the preferred

systems for commercial production. However, for the experiment

described in Paper II, earthen ponds lined with plastic sheets were

used as this facilitated establishing the required degree of

replication of the treatments.

3.3. Earthworm as a

feed source for livestock and frog production

Contribution of earthworm to our ecosystem is often

underestimated. Not only improving degradation rate of the waste,

they could be used as animal feed as containing high protein

content and many important amino acids (Parlevliet 1997).

3.3.1. Significance of Earthworm in animal

production

Earthworm can be used as feed ingredient for fish, poultry,

amphibians and pigs. They can be mixed with other feed ingredients

such as rice brume, broken rice and others (Samphone et al.,

1999). Such mixed feed ensure rapid growth of animals which can

tolerate hash environmental conditions and diseases Parlevliet

(1997).

3.3.2. Feed and feeding of

Earthworm

Earthworms live in holes they made in the soil. Earthworm intake

food through the mouth and discharge through the other end the

holes in the soil are very small in size and folds themselves in

the holes. They normally do not appear on the surface during day

time except when there is a heavy rain. Usually Earthworm can be

found on soil surface at night especially after the rain. When the

weather is dry and cold digs their holes as deep as 2.5 meters, and

under such environmental condition, Earthworm will twist themselves

around one another to form a crump and release sticky liquid

substance. At night Earthworm will feed on plant materials on the

surface and return to their holes after discharging waste materials

close to their holes (Vineset et al., 1997).

3.3.3. Nutritive value of

earthworms

Sun-dried earthworms, Perionyx excavatus, has

93.62% dry matter, 59.90% crude protein, 402.09 Kcal/100 g gross

energy, 7.43% fatty acid, 7.43% crude fibre, 1.73% Ca, and 0.118% P

(Bay, 2002). Earthworm meal is very high in protein, and with

variable oil content (Table 1). The dry matter content of

earthworms ranges between about 15 and 20%. The fatty acid

composition of the lipid extracted from worms is quite similar to

the lipid composition of some fish oils, being high in φ-3

polyunsaturated lipids. In our study natural earthworms had average

protein (70% in dry matter (DM)) and fat (13 % in DM) contents.

However, they have a comparative advantage over other forms of

recycling when the faeces are from goats or rabbits (Nguyen Quang

Suc et al., 2000). Recently, the use of the earthworm

(Eisenia foetida) as an agent for recycling live

stock manure has received increasing attention (Preston and

Rodríguez, 2002).

|

Table 1. Chemical composition of earthworms (g/kg DM basis, except for DM which is on fresh basis) |

||||||||

|

|

DM |

Crude |

Organic matter |

Crude fat |

Crude fibre |

Ash |

Ca |

P |

|

Earthworm |

214 |

572 |

952 |

79.4 |

11.2 |

48.1 |

14.5 |

7.0 |

|

DM = dry matter, Ca = calcium, P

= phosphorous |

||||||||

|

Table 2. Amino acid content in earthworm (P. excavatus) (g/16g N) |

||

|

|

(Tram et al 2005) |

(Bay 2002) |

|

Aspartic |

5.56 |

6.51 |

|

Glutamic |

12.47 |

12.64 |

|

Serine |

4.28 |

4.15 |

|

Histidine |

5.05 |

5.26 |

|

Glycine |

3.86 |

2.55 |

|

Threonine |

2.18 |

2.58 |

|

Alanine |

3.25 |

2.8 |

|

Arginine |

6.36 |

10.83 |

|

Tyrosine |

4.48 |

5.96 |

|

Valine |

4.65 |

8.62 |

|

Methionine |

2.1 |

1.92 |

|

Phenylalanine |

2.16 |

2.67 |

|

Isoleucine |

4.79 |

8.14 |

|

Leucine |

6.06 |

7.72 |

|

Lysine |

3.58 |

3.48 |

|

Hydroxyproline |

4.24 |

- |

|

Proline |

3.17 |

2.65 |

3.4. Nutritivevalue of

fly larvae

House fly (Muscadomestica) larvae has 30% DM and, in the DM, 63% protein and 15% fat according to Newton et al., (1977). By contrast, in Paper 11 it was found that the protein was lower (49% in DM) and the fat much higher (31% in DM). Due to the protein content, the fly larval meal is considered to be a suitable replacement for conventional protein and fat sources. Comparative amino acid profiles of the proteins of fishmeal and house fly larvae are in Table 3.

|

Table 3. Comparative amino acid profile of the proteins of fishmeal and house fly larvae (g /16g N) |

||

|

|

Fish meal |

Fly larvae |

|

Alanine |

6.34 |

6.15 |

|

Arginine |

5.82 |

5.42 |

|

Aspartic |

9.35 |

10.8 |

|

Cystine |

0.70 |

0.82 |

|

Glutamic |

13.3 |

12.2 |

|

Glycine |

5.90 |

5.40 |

|

Histidine |

2.22 |

3.50 |

|

Isoleucine |

4.85 |

4.13 |

|

Leucine |

7.35 |

6.95 |

|

Lysine |

7.85 |

7.37 |

|

Methionine |

2.84 |

2.24 |

|

Phenylalanin |

4.35 |

6.95 |

|

Proline |

4.35 |

3.66 |

|

Serine |

4.55 |

4.51 |

|

Threonine |

4.55 |

4.53 |

|

Tryptophan |

1.33 |

1.45 |

|

Tyrosine |

3.45 |

8.10 |

|

Valine |

5.65 |

5.60 |

|

Source: Spinelli No date |

||

3.4.1. Larvae as a

feed source for livestock production

Fly larvae (Mosca spp) have been fed experimentally to

several animals, with larvae or prepupae used to replace soybean or

fish meal in a formulated diet (Sheppard. No. date). Fly larvae

feeding tests have utilized cockerels (Hale, 1973), pigs (Newton

et al., 1977) and catfish (Bondarie et al, 1987). The

larvae have been shown to be generally equal to soybean meal (and

other conventional ingredients) in feed value when fed to chicks

(Calvert et al., 1970).

3.4.2. Research on fly larvae in the

past

Complete replacement of the protein supplemented by fresh

termites or fly larvae produced on farm from waste bagasse, wood or

fresh pigs manure, and managed and harvested by household labour,

decreased the chicken feed costs by 40% and 51% respectively,

compared to the control diet (Men, 2005).

3.4.3. Production of fly

larvae

Viet Chuong (2001) investigated a production of fly larvae from

a rectangular holes, 50 x 50 cm and deep which dug and filled with

soft, damp rice straw and fresh cattle manure in alternate 15 cm

thick layers. A thin layer of rice gruel was placed on the top

straw layer. Around one kg of spoilt fish was added to attract

flies to lay their eggs, and small shelters were constructed over

the holes to protect them from rain and direct sunlight, and to

allow the flies to enter the hole easily. To maintain high humidity

2-3 litres of water were poured over the holes when the eggs had

been laid. Growing larvae were harvested 4-5 days after putting the

bait into the holes, the yields of larvae harvested after the 5

days period were very low. It was found that this method is not

suitable for producing fly larvae under these particular

experimental conditions.

3.4.4

Fly larvae and chitin

Chitin is the most widespread amino polysaccharide in nature and

is estimated annually to be produced almost as much as cellulose.

It is mainly found in arthropod exoskeletons, fungal cell walls or

nematode egg shells. However, derivatives of chitin oligomershave

also been implicated as morphogenic factors in the communication

between leguminous plants and Rhizobium and even in

vertebrates, where they may be important during early stages of

embryogenesis. Chitin is one of the most important biopolymers in

nature. It is mainly produced by fungi, arthropods and nematodes.

In insects, it functions as scaffold material, supporting the

cuticles of the epidermis and trachea as well as the peritrophic

matrices lining the gut epithelium.

Chitin is composed largely of alternating

Nacetylglucosamine residues, which are linked by b-(1-4)-

glycosidic bonds. Since hydrolysis of chitin by chitinase treatment

leads to the release of glucosamine in addition to

Nacetylglucosamine, it was concluded that glucosamine might

be a significant portion of the polymer. However, solids NMR

analysis of tobacco hornworm cuticle preparations suggested that

little or no glucosamine is present (Kramer et al., 1995). Chitin

polymers tend to form microfibrils (also referred to as rods or

crystallites) of ~3·nm in diameter that are stabilized by

hydrogen bonds formed between the amine and carbonyl groups. Chitin

microfibrils of peritrophic matrices may even exceed 0.5·mm in

length and frequently associate in bundles containing parallel

groups of 10 or more single microfibrils (Peters et al., 1979;

Lehane, 1997). X-ray diffraction analysis suggested that chitin is

a polymorphic substance that occurs in three different crystalline

modifications, termed a-, b- and g- chitin. They mainly differ in

the degree of hydration, in the size of the unit cell and in the

number of chitin chains per unit cell (Rudall and Kenchington,

1973; Kramer and Koga, 1986). In the a form, all chains exhibit an

anti-parallel orientation; in the b form the chains are arranged in

a parallel manner; in the g form sets of two parallel strands

alternate with single antiparallel strands. In addition,

non-crystalline, transient states have also been reported in a

fungal system (Vermeulen and Wessels, 1986). All three crystalline

modifications are actually found in chitinous structures of

insects. The a form is most prevalent in chitinous cuticles,

whereas the b and g forms are frequently found in cocoons

(Kenchington, 1976; Peters, 1992). Peritrophic matrices usually

consist of a- and b-chitin. Sometimes the presence of b-chitin in

cocoons is traced back to the fact that some cocoons are formed

from peritrophic matrices; for example, those of Australian spider

beetle Ptinus tectus, a specialized beetle (Rudall

and Kenchington, 1973). The anti-parallel arrangement of chitin

molecules in the a form allows tight packaging into chitin

microfibrils, consisting of ~20 single chitin chains that are

stabilized by a high number of hydrogen bonds formed within and

between the molecules. This arrangement may contribute

significantly to the physicochemical properties of the cuticle such

as mechanical strength and stability (Giraud-Guille and Bouligand,

1986). By contrast, in the b- and g-chains, packing tightness and

numbers of inter-chain hydrogen bonds are reduced, resulting in an

increased number of hydrogen bonds with water. The high degree of

hydration and reduced packaging tightness result in more flexible

and soft chitinous structures, as are found in peritrophic matrices

or cocoons. The picture drawn above is certainly oversimplified and

does not explain the physicochemical properties of cuticles and

peritrophic matrices adequately because it is reduced to only one

component of a complex structure. However, differences in the

arrangement of chitin microfibrils between cuticles and peritrophic

matrices may help to understand their function. The cuticle is

secreted in the form of thin layers by the apical microvilli of

epidermal cells. The chitin microfibrils are embedded into the

protein matrix and stabilize it in a way that resembles

constructions of steelreinforced concrete. Since horizontal

microfibrils, in parallel with the cuticle plane, rotate either

progressively or abruptly from one level to another, complex

patterns (e.g. helicoidal) and textures (e.g. plywood-like

structures) arise, depending on the degree of rotational

displacement (Bouligand, 1972). By contrast, in peritrophic

matrices, the microfibrils are normally arranged as a network of

randomly organized, felt-like structures embedded in an amorphous

matrix, and only in a few cases have higher ordered configurations

been reported (Lehane, 1997).

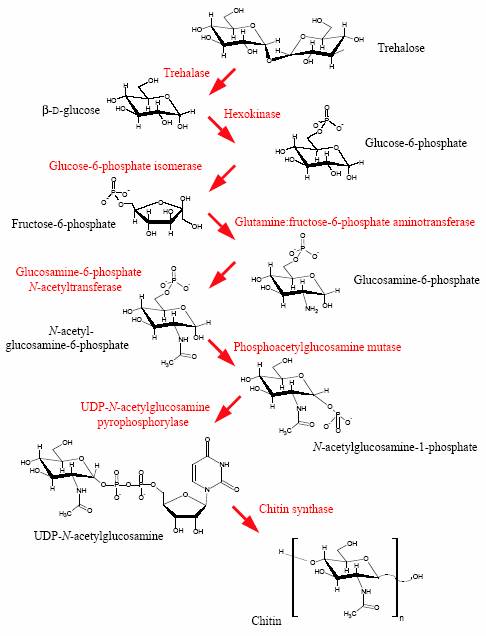

Figure.1. Biosynthesis of chitin in insects. The pathway starts

with trehalose, the main hemolymph sugar in most insects, and ends

with the chitin polymer. The diagrammatic representation is based

on previously published pathways (Kramer and Koga, 1986; Cohen,

2001).

Chitin, an integral part of the invertebrate cuticle

(exoskeleton), can be estimated by determining the acid detergent

fiber fraction corrected for ash. Since chitin contains about 7%

nitrogen, each 1% of ADF (presumed to be chitin) contains the

equivalent of 0.4% crude protein (1 x 0.07 x 6.25). It has been

reported, that some insectivores have an intestinal chitinase,

while others may rely on chitinases produced by gut microorganisms.

Chitin digestibility in three species of mammals has been shown to

range from 2-20%. However, there is no evidence that the nitrogen

released can contribute to the protein available for absorption by

the insectivore (Bernard et al., 1997).

Assuming the chitin content of the fly larvae in Paper 2 was

25%, then the protein present in the chitin would be about 6%. This

would reduce the available protein from 49% of the DM to 43% which

is still above the estimated requirements of 37% in DM.

3.5. Biodigestersin

integrated farming systems

Biodigester technology for converting manure into methane for

fuel is neither new nor uncommon. In many parts of Asia, Central

America and Europe, biodigester use is widespread. Biodigesters are

installed in these areas in response to organic waste (manure)

disposal problems and/or high-energy costs (Figure

2.)

Figure.2.Biodigester Schematic

3.6. Duckweed

Conventional feed such as soya bean meal and fish meal are a

source of protein in diets for pigs and poultry. Soya bean meal and

fish meal are expensive, which results in high costs of production.

Using of local feed resources can be a way to reduce cost of

production, and as a result, increasing income. Thus, these improve

the standard of living of smallholder farmers. Duckweeds have

potential as protein sources when combined with energy-rich feeds

which are low in fiber such as broken rice, cassava root meal or

sugar cane juice (Becerra et al., 1995). Duckweed grows well

on pond surfaces. They are more resistant to pests and diseases

than other aquatic plants and have high protein and carotene

content. Protein content of duckweed responds quickly to nutrients

in a water environment (Leng et al., 1994). The effluents

from biodigesters, when suitably diluted, are very effective media

for growing duckweed (Le Ha Chau 1998). Duckweed has high crude

protein content and a well-balanced amino acid profile and is also

a good source of vitamins and minerals for livestock. Even though

the moisture content of duckweed can be a limiting factor for fish

and also frog production, duckweed can play important role in

aquatic systems. The effluent leaving the biodigester

retains the minerals and with suitable dilution is a good media for

duckweed ponds. Ponds fertilized with effluent can produce up to

100 g fresh duckweed/m²/day which is equivalent to about 6

tonnes protein/ha/year (Rodriguéz et al., no

date).

|

Table 4. Chemical composition of duckweed |

||

|

|

Ngyuyen Thi Thuy and Ogle (2005) |

Nguyen Thi Kim Khang and Ogle (2004) |

|

DM % |

5.66 |

4.7 |

|

% of DM |

|

|

|

CP |

35 |

37.3 |

|

EE |

10.5 |

9.62 |

|

CF |

6.95 |

5.85 |

|

Ca |

1.02 |

0.9 |

|

P |

1.04 |

1.5 |

|

Ash |

16.9 |

17.9 |

|

ME (MJ/kg) |

10.2 |

9.3 |

3.7. Water quality

parameters for Frogs

An abundant supply of high quality water must be readily

available to the frogs throughout the growing season. (Diana et

al., 1997) Water temperatures of 18o-22oC

are generally suitable for rearing larval salamander species found

in Laos, and temperatures of 18o-22oC are

suitable for most species of frog. Uodone (2004), the data from

frog training course at the fishery station belong to Living

Aquatic Recourse Research Center found that water quality

parameters for available to the frogs growing in Laos in (Table. 5)

suitable for most species of frog.

|

Table 5. The condition of water source for frogs growing |

||||

|

Level |

Menu |

Unit |

6 Am |

6 Pm |

|

1 |

pH value |

|

5.5 |

7.7 |

|

2 |

Dissolved oxygen |

ppm (mg/) |

5.6 |

7.2 |

|

3 |

NH3 -H |

ppm (mg/L) |

0.04 |

0.05 |

|

4 |

Water temperature |

°C |

26.5 |

27.8 |

|

5 |

Air temperature |

°C |

27.9 |

28.6 |

|

6 |

Free from Pollution |

|

|

|

|

Source: Uodone (2004) |

||||

4.

Conclusions and recommendations

Based on the results in this thesis, it is concluded

that:

-

Frog cultivation in a waste recycling system is important for sustainable aquaculture, to reduce expenditure on costly feeds.

-

Earthworms, Larvae and Duckweed could be the basis of a system to replace the high protein concentrate feed traditionally used in intensive frog culture.

-

Pig manure mixed with fermented fish waste was a better substrate for growing larvae than Jackfruit waste and pig manure.

-

There appeared to be no advantages from applying biodigester effluent to the substrates.

-

Growth rates and feed conversion (for DM and crude protein) were better, and mortality was lower, when frogs were fed earthworms rather than larvae and when they had access to fresh duckweed mixed with the larvae/earthworms.

-

The net increase in live weight (252 g in 90 days) on the best diet (earthworms plus duckweed) was better than in one report concerning frogs fed an artificial diet (200 g in 120 days).

-

Comparisons with another aquatic species (catfish) indicated broadly similar results for growth rate and feed conversion.

5.

References

AkasayN 1994 Frog culture for Commerce trade,

Cooperative Frog culture, Thailand, 10-20 p.

BouligandY 1972 Twisted fibrous arrangements in

biological materials and cholesteric

mesophases. Tissue Cell 4, 189-217

BondariK and Sheppard DC 1987 Soldier fly,

Hermetiaillucens L., larvae as feed for

channel

catfish, Ictalurus. www.p2pays.org/ref/13/12648.htm

Becerra M, Preston TR and Ogle B 1995 Effect of replacing

whole boiled soyabeans with

Lemnasp in diets of growing ducks. MSc. Thesis, Swedish

University of Agricultural Sciences.

Bernard J B, Allen Mary E and Ullrey D E 1997 Feeding

captive insectivorous animals:

Nutritional aspects of insects as food. Nutrition Advisory

Group Handbook.

BakkersJ, Kijne J W and Spaink H P 1999 Function

of chitin oligosaccharides in plant and

animal development. EXS 87,71 -83.

[Medline]

BayNV2002 Study of production and

utilization earthworms (perionyx excavatus) as feed

Supplement in chicken diet in oder to improve scavenging chicken

production system at farmers

level. Doctoral thesis. pp. 160.

Calvert C C, NO Morgan and R D Martin 1970 House fly

larvae: biodegradation of Hen

excreta to useful products.

Poultry Science, 49,

588-9.

Cohen E 2001 Chitin synthesis and inhibition: a revisit.

PestManag. Sci.57, 946-950.

Diana J S, Szyper J P, Batterson TR, Boyd C E and Piedrahita

R H 1997 water quality in

Ponds. In: Egna, H., S, Boyd, C., E (Eds), Dynamics of pond

Aquaculture. CRC press LLC, New

York, pp.53

Giraud-GuilleM M and Bouligand Y 1986

Chitin-protein molecular organization in

arthropods. In Chitin in Nature and Technology (ed. R.

Muzzarelli, C. Jeuniaux and G. W.

Gooday), pp. 29-35. New York: Plenum Press.

Greg, Lutz C and Jimmy L A 1999

Bullfrog Culture,

Southern Regional Aquaculture Center

Through Grant No, 94-38500-0045 from the Unites States

Department of Agriculture,

Cooperative States Research, Education and Extension Service, SRAC Publication No, 436.

http://govdocs.aquake.org/cgi/reprint/2003/724/7240150.pdf

Halter S Biodigester Development in

Saskatchewan

www.csale.usask.ca/PDF Documents/biodigester

Develop.pdf)

Hale O M 1973 Dried Hermetia illucens

larvae (Stratiomyidae) as a feed additive for poultry.

J.

Ga.Entomol. Soc. 8: 16-20.

KenchingtonW 1976 Adaption of insect peritrophic

membranes to form cocoon fabrics. In The

Insect Integument (ed. H. R. Hepburn), pp. 497-513.

Amsterdam: Elsevier Science.

KamonphoneT1977

Experiment Frog culture in Annual

Report 1966, Department of Fisheries,

Bangkok50-81 p.

Kramer K J and Koga D 1986 Insect chitin: physical state,

synthesis, degradation and metabolic

regulation. Insect Biochem. 16, 851-877.

Kramer K J, Hopkins T L and Schaefer J 1995 Applications

of solids NMR to the analysis of

insect sclerotized structures. Insect Biochem. Mol.

Biol. 25, 1067-1080.

LengRA, Stambolie JH and Bell RE 1994 Duckweed a

potential high protein feed resource for

Domestic animals and fish In: Improving animal production

systems based on local feed

resources. 7th AAAP Animal Science Congress

100-117.

LehaneM J 1997 Peritrophic matrix structure and

function. Annu. Rev.Entomol. 42,

525-550.

LARReC 2001 Memorandum and frog survey in Vientiane

prefecture, Living Aquatic Resources

ResearchCenter, dated 9/4/02.

LiengK, Phanousith S and Vongvichith B 2003Frog

Breeding and Nursing from Frog nursing

in Cage by used different feed, faculty Agriculture, National

University of Laos. Page. 32.

MarttinezI P, Herrez M P and Alvalez R 1993

Optimum Level of Dietary Protein For

Rana

pereziSeane larvae. Aquaculture and Fisheries

Management.271-278 p.

Men B X, Ogle B and T R Preston 2005

Production and

evaluation of Black Soldier fly larvae

and Termites as protein supplements for chickens http://www.mekarn.org/proctu/men25.htm

NewtonGL, CV Booram, RW Barker and OM Hale 1977

Dried Hermetiaillucens larvae

meal

As a supplement for swine. J. Anim. Sci., 44,

395-400

Nguyen Quang Suc, Le Thi Ha and Dinh Van Binh 2000 Manure

from rabbits, goats, cattle

And Buffaloes as substrate for earthworm. Workshop- seminar

"Making better use of local feed

resources" (Editor: T R Preston, B Ogle and Luu Trong Hieu)

SAREC-UAF, January, 2000, Ho

Chi Minh city, Vietnam http://www.mekarn.org/sarpro/sucew.htm

Peters W, Heitmann S and Haese J 1979 Formation and fine

structure of peritrophic

membranes in the earwig, Forficula auricularia.

Entomol. Gen. 5, 241-254.

Peters W 1992 Peritrophic membranes. In

Zoophysiology, vol. 30 (ed. S. D. Bradshaw,

W.

Burggren, H. C. Heller, S. Ishii, H. Langer, G. Neuweiler and D.

J. Randall), pp. 1-238. Berlin:

Springer.

ParlevlietG J 1997 Aqriculture westem Australiq

Senior Department officer south perth.6.P

(English).

PrestonTR and Rodríguez L 2002 Low-cost

biodigesters as the epicenter of ecological farming

systems; International Workshop on Research and Development on

Use of Biodigesters in SE

Asiaregion. Eds: Preston T.R., Nguyen Duong Khang. Ho Chi Minh

City, Vietnam, 10-11 March

2002. http://www.mekarn.org/procbiod/pres.htm

Rodriguez l and Preston T R No date Productive use of

livestock wastes; a manual for the use

of biodigester effluent and ponds for duckweed

production....

www.fao.org/WAICENT/FAOINFO/AGRICULT/AGA/AGAP/FRG/Recycle/dweed/mandw.htm

RudallK M and Kenchington W 1973 The chitin

system. Biol. Rev.48, 597-636.

Sheppard C No date Black Soldier Fly and Others for

Value-Added Manure Management.

http://www.virtualcentre.org/en/enl/vol1n2/article/ibs_conf.pdf

SpinelliNo dateAquaculture development and

coordination programme, Fish feed technology.

http://www.fao.org/docrep/X5738E/x5738e0d.htm

SamphoneK and P Bounsuang 1999 Culturing

earthworms on training course in Vietiane city,

Laos. Page. 7.

ThongyountT 2004Reported Frog Processing and Frog

Culture, Faculty of Fisheries

Latsmongkhon Technology Institute. 10-35 p. Natural and Semi

artificial, Living Aquatic

Resource Research Center, National Agriculture and forestry

Research Institute, Ministry of

Agriculture and forestry. 15-30 p.

Tram N D Q 2005

Culturing earthworms on pig manure and

the effect of replacing trash fish by

earthworms on the growth performance of catfish (MEKARN MSc

2003-2005.

Uodone2004 Frog hatchery on training course in

Vietiane city, Laos. Page. 12.

VermeulenC A and Wessels J G 1986 Chitin

biosynthesis by a fungal membrane preparation.

Evidence for a transient non-crystalline state of chitin.

Eur. J. Biochem. 158, 411-415.

Vines A E ND N Rees 1997 Plant and Animal biology volume

L, Department, the college of st.

Mark and st. John, cheisea, PP 6-603 (Enhlish).

Viet C 2001 Preduction of larvae and earthworms to feed

farm animal. Ho Chi Minh Publishing House. pp. 47-68