Effect of fertilization with biodigester effluent on

substrates of fruit waste or fermented fish waste, each mixed with

pig manure, for growth of larvae from House flies

LatsamyPhounvisouk and T R Preston*

Living Aquatic Resources Research Center

(LARReC),

NAFRI, Vientiane, Laos

Meetouna@yahoo.com

* TOSOLY, UTA-Colombia, AA#48, Socorro, Santander, Colombia

Abstract

An experiment was carried out to investigate the use of

fermented fish or jackfruit, together with pig manure, as

substrates for production of larvae, and to determine if there were

advantages in adding biodigester effluent to the substrates. The

experiment was a 2*4 arrangement, the factors being: Substrate

(fermented fish waste + pig manure or Jackfruit waste + pig manure)

and Biodigester effluent (application of 100, 150, 200 or 250 mg

N/m2 of substrate surface). There were 2 replicates of

each treatment in a completely randomized design. The substrates

were put in brick-lined enclosures with floor area of 0.25 m².

The substrates were rapidly colonized by house flies (Mosca

spp) and the larvae appeared within 20 to 24 hours after

introducing the substrates. Six days after introducing the

substrates, the larvae were harvested by immersing the substrates

in water, and collecting the larvae which remained floating on the

water surface.

The production of larvae was higher on the substrate with fish

waste than on the fruit waste. There was no effect of the level of

effluent and no interaction between substrate and effluent.

Conversion rates were better for the substrates with fermented

fish: 9 kg waste DM to 1 kg larval DM and 3.5 kg crude protein in

the waste to 1 kg of protein in the larvae.

It is concluded that pig manure mixed with fermented fish waste

is a better substrate for growing larvae than Jackfruit waste and

pig manure. There appeared to be no advantages from applying

biodigester effluent to the substrates.

Key words: biodigester effluent, fly larvae,

recycling, substrates

Introduction

The cultivation of fly larvae using local resources such as

livestock manure would seem to be a valuable intervention for

generating a source of high quality protein that can be used as

animal feed. The common housefly (Muscaspp.) and the

Black Soldier fly (Hermetia illucens) possess some

merits such as a short life cycle (Greene et al 1998). The

adult females can lay eggs in many breeding materials. The larvae

that hatch from the eggs scavenge for the protein in waste

materials and accumulate it in their biomass. Thus, for sustainable

development and environment protection, fly larvae can be a

valuable biological component to support use of farm residue

management and recycling in integrated farming systems (Shepperd No

date).

Based on the above discussion, it is important to draw attention

to the need to begin culture of fly larvae using agricultural and

industrial wastes as the substrate. If such wastes are not used nor

managed effectively, they will be harmful to human health and the

environment because wastes are birth place of diseases, which are

harmful to both humans and animals (Marc et al 2004).

Because fly larval biomass is rich in both protein and fat

(Sheppard No date), the larvae would seem to be especially

appropriate for feeding to frogs, which are carnivorous animals

requiring high levels of protein and energy in their diet. The

objective of the following experiment was to investigate the use of

different waste materials, from fermented fish and jackfruit,

together with pig manure as substrates for production of larvae,

and to determine if there were advantages in adding biodigester

effluent to the substrates.

The hypotheses were that larval production will be

higher:

-

On a substrate of fermented fish residue mixed with pig manure compared with use of jackfruit waste and manure.

-

When effluent from a biodigester is added to the substrates

Materials and Methods

Location

The experiment was carried out from 15th May to 15th

October 2006.at the Living Aquatic Resource Research Center in

Naong Taeng District, Vientiane Province, Laos

Experimental treatments and

design

The experiment was a 2*4 arrangement of the following factors

according to a Completely Randomized Design. The treatments

were:

Substrate

-

FIW: Fermented fish waste + pig manure

-

FRW: Jackfruit waste + pig manure

Biodigester effluent

-

100E: 100 mg N/m2 of substrate

-

150E: 150 mg N/m2 "

-

200E: 200 mg N/m2 "

-

250E: 250 mg N/m2 "

There were 2 replicates of each treatment in a completely

randomized design.

Cultivation of the larvae

The larvae were cultivated in enclosures made from bricks. Each enclosure had surface area of 0.25 m² (50*50 cm) and a depth of 20 cm (Photo 1). The floor of the enclosure was made of concrete with a 15% slope at the entrance to facilitate the escape of the larvae. The enclosures were roofed with panels made of dried grass.

|

|

|

|

Substrates

These were composed of mixtures of fresh pig manure and the

waste from either fermented fish or jackfruit (Artocarpus

heterophyllus). The proportions (fresh basis) were: 70%

manure and 30% fish or fruit waste.

Pig manure

Manure was collected from the floor of the pens of pigs fed a

diet of maize (30%), brewer's grains (30%) and concentrate

supplement (20%).

Fermented fish waste

The waste was the residue from fish which had been processed for

production of fish sauce. In this process the fish, after removal

of the digestive tract, are fermented with rice bran, salt, garlic,

yellow grass and water during a period of from 6 months to 1 year.

At the end of this time, the fermented product is boiled and the

liquid separated for sale for human consumption. The residue after

separation of the liquid is normally thrown into the Mekong River

as feed for fish. For the experiment the waste was collected from

the market at weekly intervals.

Jackfruit waste

This was the flesh and fibrous residue from Jackfruit, not used

for human consumption, which normally is used as feed for cattle

and buffaloes. It was collected daily from the local

market.

Biodigester effluent

The effluent was collected from a tubular polyethylene biodigester (photo 2) charged with the same pig manure used as substrate for the larvae. The biodigester was 6m long with diameter of 1m giving a total volume of 4.7m3. It was filled initially with 270 kg of pig manure and 300 litres of water. Subsequently, at weekly intervals, 36 kg pig manure and 130 litres water were added.

|

|

|

|

|

|

||

Production of larvae

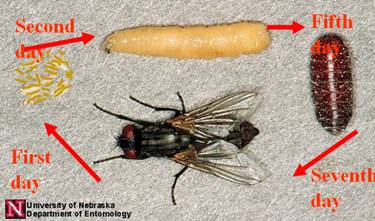

The first step was to put 7 kg of fresh pig manure in each of the enclosures. Three kg of fermented fish waste or 3 kg of jackfruit waste (3 kg) were then placed on top of the pig manure. The appropriate quantities of biodigester effluent were sprayed on the surface of the substrates on days 1, 3 and 5. In a preliminary observation it was observed that larvae appeared within 24 hours of putting the substrate in the containers. The larvae were white in co lour (Photo 3) and were very active.

|

|

|

|

On the basis of the co lour and size of the larvae, and the short period (less than 24 hours) from introduction of the substrate to appearance of larvae, it was concluded that they were from the common house fly (Mosca spp) (Figure 1).

|

|

|

|

On day 6 the larvae/pupae were harvested by putting the contents

of each enclosure (substrate plus larvae) into a pond filled with

water. The substrate sank to the bottom of the pond leaving the

larvae floating on the surface. The larvae were then

collected.

Measurements

Samples of fresh larvae and of the fresh substrates were

analysed for dry matter (DM), nitrogen and fat, according to AOAC

(1990) procedures.

Statistical analysis

The data were analysed using the General Linear Model option in the ANOVA programmer of Minitab (2002) (version 3.2). Sources of variation in the model were: Source of substrate (fish waste or fruit waste), quantity of biodigester effluent, the interaction substrate*effluent and error.

Results

The dry matter content and the content of nitrogen in the dry matter were higher for the fermented fish waste than for the fruit waste (Table 1). The values for the jackfruit waste were similar to those reported in Indonesia (19.8% DM and 1.33% N in DM) (Kusmartono, 2007). The N concentration of the biodigester effluent and the proportion in the form of ammonia were in the range (889 to1690 mg N/litre and 0.40 to 0.60 for proportion of N as ammonia) reported by (San Thy et al 2003) for tubular plastic biodigesters charged with pig manure in Cambodia.

|

Table 1. Mean values for concentration of DM, ether extract and nitrogen in the substrates and of N in the biodigester effluent |

||||

|

|

Pig |

Jackfruit waste |

Fermented fish waste |

Biodigester |

|

DM, % |

27.8 |

15.3 |

41.9 |

|

|

Nitrogen, % in DM |

3.09 |

1.38 |

3.51 |

|

|

Ether extract, % in DM |

ND |

6.09 |

5.32 |

|

|

Total N, mg/litre |

|

|

|

1010 |

|

NH3-N/total N |

|

|

|

0.65 |

|

ND: Not determined |

||||

Composition of the larvae in the present experiment compared with reports in the literature are in Table 2.

|

Table 2. Composition of the larvae in the present experiment compared with reports in the literature |

|||

|

|

DM |

Crude protein, |

Ether extract, |

|

Fermented fish |

22.2 |

49.5 |

31.5 |

|

Jackfruit |

22.0 |

49.0 |

6.09 |

|

House fly larvae |

30.0 |

52.2 |

28.7 |

|

House fly larvae# |

|

63 |

9-15 |

|

# Shepherd (No date) |

|||

The production of larvae was higher on the substrate with fish waste than on the fruit waste (P=0.028). There was no effect of the level of effluent and no interaction between substrate and effluent. The results are therefore presented for the main effects (Tables 3 and 4). Conversion rates were better for the substrates with fermented fish, with conversion rates for DM of 9 kg waste DM to 1 kg larval DM and for protein of 3.5 kg crude protein in the waste to 1 kg of protein in the larvae.

|

Table 3. Mean values for production parameters of larvae growing in pig manure mixed with either fish or fruit waste and biodigester effluent |

||||

|

|

Fruit |

Fish |

SEM |

Prob. |

|

Substrate, g fresh material |

|

|

||

|

Pig manure |

7000 |

7000 |

|

|

|

Fish waste |

|

3000 |

|

|

|

Fruit waste |

3000 |

|

|

|

|

Effluent |

347 |

347 |

|

|

|

Total DM |

251 |

330 |

|

|

|

Total N*6.25 |

44.6 |

655 |

|

|

|

Larvae, g |

|

|

||

|

Fresh matter |

696 |

1186 |

120 |

0.028 |

|

DM |

209 |

356 |

|

|

|

N*6.25 |

109 |

186 |

|

|

|

Conversion of substrate to larvae |

|

|

||

|

DM# |

11.5 |

9.00 |

|

|

|

N*6.25## |

3.81 |

3.51 |

|

|

|

# g DM in

substrate/g of larvae DM |

||||

|

Table 4. Mean values for production parameters of larvae growing in pig manure and either fish or fruit waste according to application of biodigester effluent |

||||||

|

|

mg N/m2 of substrate surface |

|

|

|||

|

|

100 |

150 |

200 |

250 |

SEM |

Prob. |

|

Substrate, g |

|

|

|

|

|

|

|

Pig manure |

7000 |

7000 |

7000 |

7000 |

|

|

|

Fish or fruit waste |

3000 |

3000 |

3000 |

3000 |

|

|

|

Effluent |

50 |

74 |

99 |

124 |

|

|

|

Total DM |

2801 |

2802 |

2803 |

2804 |

|

|

|

N*6.25 |

503 |

503 |

503 |

503 |

|

|

|

Larvae, g |

||||||

|

663 |

1004 |

1165 |

930 |

160 |

0.29 |

|

|

DM |

199 |

301 |

350 |

279 |

|

|

|

N*6.25 |

104 |

157 |

182 |

146 |

|

|

|

Conversion of substrate to larvae |

||||||

|

DM# |

14.1 |

9.3 |

8.0 |

10.0 |

|

|

|

N*6.25## |

4.84 |

3.20 |

2.76 |

3.45 |

|

|

|

# g DM in

substrate/g of larvae DM |

||||||

The higher rate of production of larvae and the apparently better conversion rates for the substrates with fish compared with fruit waste were logical consequences of the higher content of protein in the former. As the analysis of the substrates and the larvae were done on bulked samples, it was not possible to make a statistical analysis of the conversion rates for DM and crude protein.

Discussion

Papp (1974) (cited by Sheppard No Date) reported an 8%

conversion (DM basis) of pig manure to house fly larvae (equivalent

to a DM conversion of 12.5), which is similar to the overall mean

of 10.5 observed in the present study (range of 8 to 14). There

appear to be no reports on the protein scavenging capacity of the

house fly larvae. However, the observed conversion rates (range of

2.8 to 4.8 kg protein in waste to larval protein) indicate that

they are highly efficient in recovering the protein from waste

materials.

Reports in the literature indicate similar conversion rates for

manure into larvae. Sheppard et al. (1995) described an inexpensive

manure management system to convert poultry manure to house fly

larvae (containing 42% protein, 35% fat) with an 8% DM conversion

rate. According to Newton et al (2005), pig manure is the principal

food of many insects in nature, especially the larvae of the black

soldier fly and house fly. Chiou and Chen (1982) (cited by Sheppard

No Date) found that house flies converted 50 to 60% of swine fecal

mass to larval mass (presumably on fresh basis), including recovery

of up to 55% of the manure organic carbon as larval carbon. BSF

larvae converted manure in a 460 hen facility to pre-pupal biomass

at a 7.8% (DM basis) rate (Sheppard et al 1995), which

would represent 58 tonnes of pre-pupal biomass from 100,000 hens in

5 months. House flies under optimum laboratory conditions converted

poultry manure to pupae at a 7.6% rate (Miller et al

1974).

Conclusions and recommendations

-

Pig manure mixed with fermented fish waste was a better substrate for growing larvae than Jackfruit waste and pig manure.

-

There appeared to be no advantages from applying biodigester effluent to the substrates.

Acknowledgements

The authors are grateful to the Swedish International

Development Agency-Swedish Agency for research Cooperation with

Developing countries (Sida-SAREC) for supporting this study. Thanks

are also given to the staff at the pig station in Naong Thaeng

Village, Mr. Young Thong, who supported and make it possible to

conduct this study on fly larvae. Thanks are given to Mr. Thanh,

for help in installing the biodigester. Appreciation is given to

the Laboratory of the Livestock Research Center of the National

Agriculture and Forestry Institute of Laos, for analysis of the

samples.

References

AOAC 1990

In: Helrick (Ed ) Official methods of analysis. Association of

Official Analytical Chemists, Arlington, Virginia, 15th

edition, 1298 pp.

ANOVA 2002

Programmer of Minitab Statistical software Release

version 3.2. Minitab Inc, USA.

Chiou Y Y and Chen W J 1982

Production of maggot protein

produced from swine manure. K'o Hsueh Fa Chan Yueh K'an, 10:

667-682. (cited by Sheppard C No Date).

Greene G L, Sloderbeck P E and Nechols J R 1998

Biological

Fly Control for Kansas Feedlots, Kansas State University, April

1998. http://www.oznet.ksu.edu/library/entml2/mf2223.pdf

Kusmartono 2007 Effects of supplementing Jackfruit

(Artocarpus heterophyllus L) wastes with urea or

Gliricidia/cassava leaves on growth, rumen digestion and feed

degradability of sheep fed on rice straw basal diet. Livestock

Research for Rural Development.Volume 19, Article

#21. Retrieved March 30, 2007, from http://www.cipav.org.co/lrrd/lrrd19/2/kusm19021.htm

Miller B F, Teotia J S and

Thatcher T O 1974 Digestion of

poultry manure by Musca domestica.Brit. Poult.

Sci. 15: 231-234.

http://

www.food-insects.com/book7_31/Chapter 10 Western

Research.htm

Marc Erickson 2004

Brunswick Pesticide Campaign,

carcinogenic growth and cause birth defects in the children and are

consumed by both humans and animals.

http://academic.bowdoin.edu/environmental_studies/service_learning/pdf/pesticides-socio-04.pdf

Newton L, Sheppard C, Watson W E, Burtke G and Dove R 2005

Using the black soldier fly, Hermetiaillucens, as a

value-added tool for the management of swine manure.

http://www.pc.ctc.edu/coe/new%20pdfs/BlackSoldierFly_manure_control_mar1706%20(2).pdf

Papp L 1974 House fly larvae as protein source from pig

manure. Folia Entomol. Hungarica. 28: 127-136.(cited by Sheppard,

C No Date)

Sheppard D C, Newton G

L, Thompson S A and Savage S E

1994 A value added manure management system using the black

soldier fly. Bioresource Technol. 50 (1994):

275-279.

Sheppard D C No date Black Soldier Fly and Others for

Value-Added Manure Management.

www.lead.virtualcentre.org/en/enl/vol1n2/article/ibs_conf.pdf

San Thy 2003 Management and Utilization of biodigesters in

integrated farming systems.MSc.Thesis in the programme "Tropical Livestock

System". SLU, Dept. of Animal Nutrition and Management, P.O. Box

7024, Uppsala, Sweden.

http://www.mekarn.org/msc2001-03/theses03/contsant.htm

|

Table 1. Mean values for concentration of DM, ether extract and

nitrogen in the substrates and of N in the biodigester

effluent |

||||

|

|

Pig manure |

Jackfruit waste |

Fermented fish waste |

Biodigester effluent |

|

DM % |

27.8 |

15.3 |

41.9 |

|

|

Nitrogen, % in DM |

3.09 |

1.38 |

3.51 |

|

|

Ether extract, % in DM |

ND |

6.09 |

5.32 |

|

|

Total N, mg/litre |

|

|

|

1010 |

|

NH3-N/total N |

|

|

|

0.65 |

|

ND: Not determined |

||||

|

Table 2. Composition of the larvae in the present experiment

compared with reports in the literature |

|||

|

|

DM, % |

Crude protein, |

Ether extract, % in DM |

|

Fermented fish |

22.2 |

49.5 |

31.5 |

|

Jackfruit |

22.0 |

49.0 |

6.09 |

|

House fly larvae |

30.0 |

52.2 |

28.7 |

|

House fly larvae# |

|

63 |

9-15 |

|

# Shepherd (No date) |

|||

|

Table 3. Mean values for production parameters of larvae growing

in pig manure mixed with either fish or fruit waste and biodigester

effluent |

|||||

|

|

Fruit |

Fish |

SEM |

Prob |

|

|

Substrate, g fresh material |

|

||||

|

Pig manure |

7000 |

7000 |

|

|

|

|

Fish waste |

|

3000 |

|

|

|

|

Fruit waste |

3000 |

|

|

|

|

|

Effluent |

347 |

347 |

|

|

|

|

Total DM |

251 |

330 |

|

|

|

|

Total N*6.25 |

44.6 |

655 |

|

|

|

|

Larvae, g |

|||||

|

Fresh matter |

696 |

1186 |

120 |

0.028 |

|

|

DM |

209 |

356 |

|

|

|

|

N*6.25 |

109 |

186 |

|

|

|

|

Conversion of substrate to larvae |

|||||

|

DM# |

11.5 |

9.00 |

|

|

|

|

N*6.25## |

3.81 |

3.51 |

|

|

|

|

# g DM in substrate/g of larvae DM ## g N*6.25 in substrate/g N*6.25 in

larvae |

|||||

|

Table 4. Mean values

for production parameters of larvae growing in pig manure and

either fish or fruit waste according to application of

biodigestereffluent |

||||||

|

|

mg N/m2 of substrate

surface |

|

|

|||

|

|

100 |

150 |

200 |

250 |

SEM |

Prob. |

|

Substrate, g |

|

|

|

|

|

|

|

Pig manure |

7000 |

7000 |

7000 |

7000 |

|

|

|

Fish or fruit waste |

3000 |

3000 |

3000 |

3000 |

|

|

|

Effluent |

50 |

74 |

99 |

124 |

|

|

|

Total DM |

2801 |

2802 |

2803 |

2804 |

|

|

|

N*6.25 |

503 |

503 |

503 |

503 |

|

|

|

Larvae, g |

||||||

|

663 |

1004 |

1165 |

930 |

160 |

0.29 |

|

|

DM |

199 |

301 |

350 |

279 |

|

|

|

N*6.25 |

104 |

157 |

182 |

146 |

|

|

|

Conversion of substrate to larvae |

||||||

|

DM# |

14.1 |

9.3 |

8.0 |

10.0 |

|

|

|

N*6.25## |

4.84 |

3.20 |

2.76 |

3.45 |

|

|

|

# g DM in substrate/g of larvae DM ## g N*6.25 in substrate/g N*6.25 in

larvae |

||||||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|